Page 103 - Introduction to Marine Engineering

P. 103

90 Boilers

whose pressure is set by the compression nut at the top. The spring

pressure, once set, is fixed and sealed by a Surveyor. When the steam

exceeds this pressure the valve is opened and the spring compressed.

The escaping steam is then led through a waste pipe up the funnel and

out to atmosphere. The compression of the spring by the initial valve

opening results in more pressure being necessary to compress the spring

and open the valve further. To some extent this is countered by a lip

arrangement on the valve lid which gives a greater area for the steam to

act on once the valve is open. A manually operated easing gear enables

the valve to be opened in an emergency. Various refinements to the

ordinary spring-loaded safety valve have been designed to give a higher

lift to the valve.

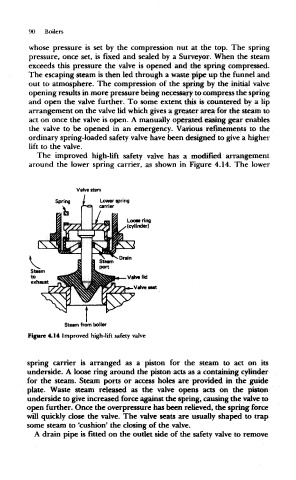

The improved high-lift safety valve has a modified arrangement

around the lower spring carrier, as shown in Figure 4.14. The lower

Valve stem

L carrier

Lower spring

toon ring

(cylinder)

Steam from boiler

Figure 4.14 Improved high-lift safety valve

spring carrier is arranged as a piston for the steam to act on its

underside. A loose ring around the piston acts as a containing cylinder

for the steam. Steam ports or access holes are provided in the guide

plate. Waste steam released as the valve opens acts on the piston

underside to give increased force against the spring, causing the valve to

open further. Once the overpressure has been relieved, the spring force

will quickly close the valve. The valve seats are usually shaped to trap

some steam to 'cushion' the closing of the valve.

A drain pipe is fitted on the outlet side of the safety valve to remove