Page 105 - Introduction to Marine Engineering

P. 105

92 Boilers

To burners

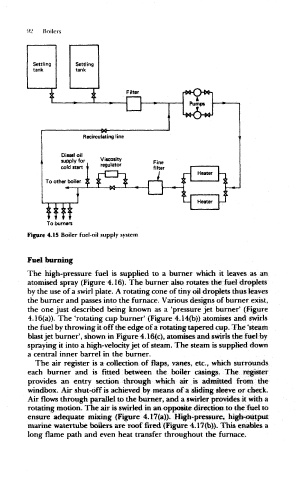

Figure 4.15 Boiler fuel-oil supply system

Fuel burning

The high-pressure fuel is supplied to a burner which it leaves as an

atomised spray (Figure 4.16). The burner also rotates the fuel droplets

by the use of a swirl plate. A rotating cone of tiny oil droplets thus leaves

the burner and passes into the furnace. Various designs of burner exist,

the one just described being known as a 'pressure jet burner' (Figure

4.16(a». The 'rotating cup burner' (Figure 4.14(b)) atomises and swirls

the fuel by throwing it off the edge of a rotating tapered cup. The 'steam

blast jet burner', shown in Figure 4.16(c), atomises and swirls the fuel by

spraying it into a high-velocity jet of steam. The steam is supplied down

a central inner barrel in the burner.

The air register is a collection of flaps, vanes, etc., which surrounds

each burner and is fitted between the boiler casings. The register

provides an entry section through which air is admitted from the

windbox. Air shut-off is achieved by means of a sliding sleeve or check.

Air flows through parallel to the burner, and a swirler provides it with a

rotating motion. The air is swirled in an opposite direction to the fuel to

ensure adequate mixing (Figure 4.17(a)). High-pressure, higb-0i»tput

marine watertube boilers are roof fired (Figure 4.17(b)). This enables a

long flame path and even heat transfer throughout the furnace.