Page 107 - Introduction to Marine Engineering

P. 107

94 Boilers

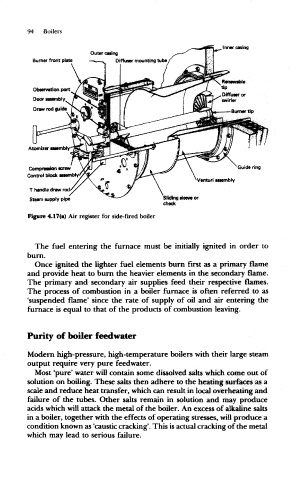

Inner casing

Outer casing

Burner front plate Diffuser mounting tube.

Observation port

Door assembly

Compression screw Guide ring

Control block assembly

Venturi assembly

Sliding sleeve or

check

Figure 4.17(a) Air register for side-fired boiler

The fuel entering the furnace must be initially ignited in order to

burn.

Once ignited the lighter fuel elements burn first as a primary flame

and provide heat to burn the heavier elements in the secondary flame.

The primary and secondary air supplies feed their respective flames.

The process of combustion in a boiler furnace is often referred to as

'suspended flame' since the rate of supply of oil and air entering the

furnace is equal to that of the products of combustion leaving.

Purity of boiler feedwater

Modern high-pressure, high-temperature boilers with their large steam

output require very pure feedwater.

Most 'pure* water will contain some dissolved salts which come out of

solution on boiling. These salts then adhere to the heating surfaces as a

scale and reduce heat transfer, which can result in local overheating and

failure of the tubes. Other salts remain in solution and may produce

acids which will attack the metal of the boiler. An excess of alkaline salts

in a boiler, together with the effects of operating stresses, will produce a

condition known as 'caustic cracking'. This is actual cracking of the metal

which may lead to serious failure.