Page 243 - Introduction to Mineral Exploration

P. 243

226 M.K.G. WHATELEY & B. SCOTT

1

253.66 m Sample

2

40° Fragment missing

15 cm

Slate

3 Chlorite and

5 cm core loss ore minerals

15 cm

hanging–wall

Chlorite and quartz

4

31 cm

Lode zone

5

15 cm

Chlorite and feldspar

23 cm

254.65 m

Core intersection angle average 40°

Slate footwall

Sample Depth Recovery True width %Sn cm%

number from(m) to(m) (m) (%) (cm)

1 253.66 253.81 0.15 100 12 0.03 0.36

2 253.81 253.96 0.15 100 12 0.56 6.72

3 253.96 254.27 0.25 81 20 4.75 95.00

4 254.27 254.42 0.15 100 12 1.27 15.24

5 254.42 254.65 0.23 100 18 NIL –

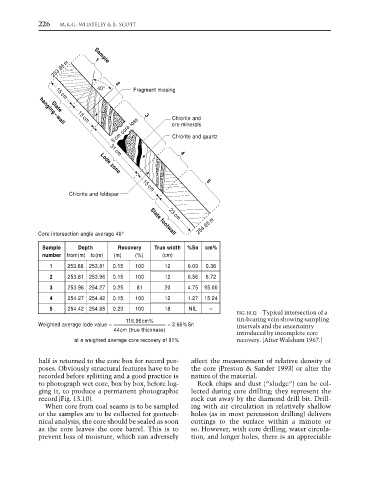

FIG. 10.12 Typical intersection of a

Weighted average lode value = 116.96cm% = 2.66%Sn tin-bearing vein showing sampling

intervals and the uncertainty

44cm (true thickness)

introduced by incomplete core

at a weighted average core recovery of 91% recovery. (After Walsham 1967.)

half is returned to the core box for record pur- affect the measurement of relative density of

poses. Obviously structural features have to be the core (Preston & Sander 1993) or alter the

recorded before splitting and a good practice is nature of the material.

to photograph wet core, box by box, before log- Rock chips and dust (“sludge”) can be col-

ging it, to produce a permanent photographic lected during core drilling; they represent the

record (Fig. 13.10). rock cut away by the diamond drill bit. Drill-

When core from coal seams is to be sampled ing with air circulation in relatively shallow

or the samples are to be collected for geotech- holes (as in most percussion drilling) delivers

nical analysis, the core should be sealed as soon cuttings to the surface within a minute or

as the core leaves the core barrel. This is to so. However, with core drilling, water circula-

prevent loss of moisture, which can adversely tion, and longer holes, there is an appreciable