Page 244 - Introduction to Mineral Exploration

P. 244

10: EVALUATION TECHNIQUES 227

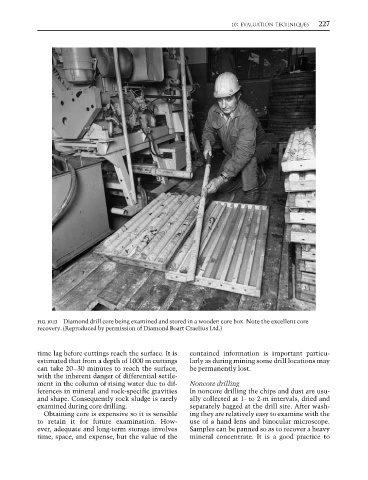

FIG. 10.13 Diamond drill core being examined and stored in a wooden core box. Note the excellent core

recovery. (Reproduced by permission of Diamond Boart Craelius Ltd.)

time lag before cuttings reach the surface. It is contained information is important particu-

estimated that from a depth of 1000 m cuttings larly as during mining some drill locations may

can take 20–30 minutes to reach the surface, be permanently lost.

with the inherent danger of differential settle-

ment in the column of rising water due to dif- Noncore drilling

ferences in mineral and rock-specific gravities In noncore drilling the chips and dust are usu-

and shape. Consequently rock sludge is rarely ally collected at 1- to 2-m intervals, dried and

examined during core drilling. separately bagged at the drill site. After wash-

Obtaining core is expensive so it is sensible ing they are relatively easy to examine with the

to retain it for future examination. How- use of a hand lens and binocular microscope.

ever, adequate and long-term storage involves Samples can be panned so as to recover a heavy

time, space, and expense, but the value of the mineral concentrate. It is a good practice to