Page 251 - Introduction to Naval Architecture

P. 251

236 PROPULSION

as the propeller revolutions and slip increase. Tip vortex cavitation is

next to appear, resulting from the low pressure within the tip vortex, As

the pressure on the back of the blade falls further the cavitation extends

from the leading edge across the back until there is a sheet of cavitation.

When the sheet covers the whole of the back of the blade the propeller is

said to be fully cavitating or super-cavitating. Propellers working in this

range do not experience erosion on the back and the drag due to the

frictional resistance to flow over the back disappears. Thus when fairly

severe cavitation is likely to occur anyway there is some point in going to

the super-cavitation condition as the design aim. Super-cavitating propellers

are sometimes used for fast motor boats.

Flat faced, circular back sections tend to have a less peaky pressure

distribution than aerofoil sections. For this reason they have often been

used for heavily loaded propellers. However, aerofoil sections can be

designed to have a more uniform pressure distribution and this

approach is to be preferred. For a given thrust, more blades and

greater blade area will reduce the average pressures and therefore the

peaks. It will be found that heavily loaded propellers have much

broader blades than lightly loaded ones.

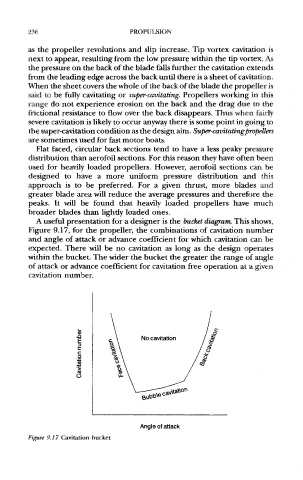

A useful presentation for a designer is the bucket diagram. This shows,

Figure 9.17, for the propeller, the combinations of cavitation number

and angle of attack or advance coefficient for which cavitation can be

expected. There will be no cavitation as long as the design operates

within the bucket. The wider the bucket the greater the range of angle

of attack or advance coefficient for cavitation free operation at a given

cavitation number.

Figure 9,17 Cavitation bucket