Page 296 - Introduction to Petroleum Engineering

P. 296

284 RESERVOIR PERFORMANCE

Plan view

Stimulated

Well pad

region

FIgURE 14.10 Sketch of wellbore trajectories drilled from a shale development well pad.

Compressors Storage tanks

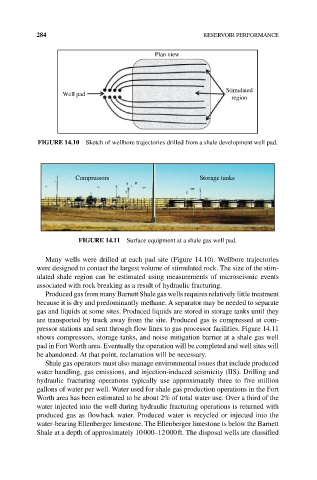

FIgURE 14.11 Surface equipment at a shale gas well pad.

Many wells were drilled at each pad site (Figure 14.10). Wellbore trajectories

were designed to contact the largest volume of stimulated rock. The size of the stim‑

ulated shale region can be estimated using measurements of microseismic events

associated with rock breaking as a result of hydraulic fracturing.

Produced gas from many Barnett Shale gas wells requires relatively little treatment

because it is dry and predominantly methane. A separator may be needed to separate

gas and liquids at some sites. Produced liquids are stored in storage tanks until they

are transported by truck away from the site. Produced gas is compressed at com‑

pressor stations and sent through flow lines to gas processor facilities. Figure 14.11

shows compressors, storage tanks, and noise mitigation barrier at a shale gas well

pad in Fort Worth area. Eventually the operation will be completed and well sites will

be abandoned. At that point, reclamation will be necessary.

Shale gas operators must also manage environmental issues that include produced

water handling, gas emissions, and injection‐induced seismicity (IIS). Drilling and

hydraulic fracturing operations typically use approximately three to five million

gallons of water per well. Water used for shale gas production operations in the Fort

Worth area has been estimated to be about 2% of total water use. Over a third of the

water injected into the well during hydraulic fracturing operations is returned with

produced gas as flowback water. Produced water is recycled or injected into the

water‐bearing Ellenberger limestone. The Ellenberger limestone is below the Barnett

Shale at a depth of approximately 10 000–12 000 ft. The disposal wells are classified