Page 293 - Introduction to Petroleum Engineering

P. 293

PERFORMANCE OF AN UNCONVENTIONAL RESERVOIR 281

Fort Worth Basin

North South

Montague Comanche San saba Gillespie

County Wise Parker Hood Erath Mills Llano

Cretaceous

Cisco

Barnett

Canyon

outcrops

Strawn

Lower

Penn. Llano uplift

Barnett

Muenster Ellenberger

Arch

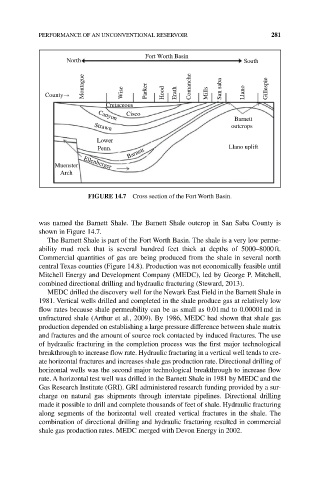

FIgURE 14.7 Cross section of the Fort Worth Basin.

was named the Barnett Shale. The Barnett Shale outcrop in San Saba County is

shown in Figure 14.7.

The Barnett Shale is part of the Fort Worth Basin. The shale is a very low perme‑

ability mud rock that is several hundred feet thick at depths of 5000–8000 ft.

Commercial quantities of gas are being produced from the shale in several north

central Texas counties (Figure 14.8). Production was not economically feasible until

Mitchell Energy and Development Company (MEDC), led by George P. Mitchell,

combined directional drilling and hydraulic fracturing (Steward, 2013).

MEDC drilled the discovery well for the Newark East Field in the Barnett Shale in

1981. Vertical wells drilled and completed in the shale produce gas at relatively low

flow rates because shale permeability can be as small as 0.01 md to 0.00001 md in

unfractured shale (Arthur et al., 2009). By 1986, MEDC had shown that shale gas

production depended on establishing a large pressure difference between shale matrix

and fractures and the amount of source rock contacted by induced fractures. The use

of hydraulic fracturing in the completion process was the first major technological

breakthrough to increase flow rate. Hydraulic fracturing in a vertical well tends to cre‑

ate horizontal fractures and increases shale gas production rate. Directional drilling of

horizontal wells was the second major technological breakthrough to increase flow

rate. A horizontal test well was drilled in the Barnett Shale in 1981 by MEDC and the

Gas Research Institute (GRI). GRI administered research funding provided by a sur‑

charge on natural gas shipments through interstate pipelines. Directional drilling

made it possible to drill and complete thousands of feet of shale. Hydraulic fracturing

along segments of the horizontal well created vertical fractures in the shale. The

combination of directional drilling and hydraulic fracturing resulted in commercial

shale gas production rates. MEDC merged with Devon Energy in 2002.