Page 294 - Introduction to Petroleum Engineering

P. 294

282 RESERVOIR PERFORMANCE

Clay

Montague

Cooke

Jack Wise Denton

Palo

Pinto Parker Tarrant Dallas

Texas Hood Johnson

Erath Ellis

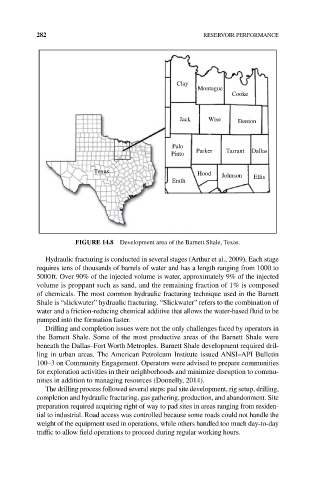

FIgURE 14.8 Development area of the Barnett Shale, Texas.

Hydraulic fracturing is conducted in several stages (Arthur et al., 2009). Each stage

requires tens of thousands of barrels of water and has a length ranging from 1000 to

5000 ft. Over 90% of the injected volume is water, approximately 9% of the injected

volume is proppant such as sand, and the remaining fraction of 1% is composed

of chemicals. The most common hydraulic fracturing technique used in the Barnett

Shale is “slickwater” hydraulic fracturing. “Slickwater” refers to the combination of

water and a friction‐reducing chemical additive that allows the water‐based fluid to be

pumped into the formation faster.

Drilling and completion issues were not the only challenges faced by operators in

the Barnett Shale. Some of the most productive areas of the Barnett Shale were

beneath the Dallas–Fort Worth Metroplex. Barnett Shale development required dril‑

ling in urban areas. The American Petroleum Institute issued ANSI–API Bulletin

100–3 on Community Engagement. Operators were advised to prepare communities

for exploration activities in their neighborhoods and minimize disruption to commu‑

nities in addition to managing resources (Donnelly, 2014).

The drilling process followed several steps: pad site development, rig setup, drilling,

completion and hydraulic fracturing, gas gathering, production, and abandonment. Site

preparation required acquiring right of way to pad sites in areas ranging from residen‑

tial to industrial. Road access was controlled because some roads could not handle the

weight of the equipment used in operations, while others handled too much day‐to‐day

traffic to allow field operations to proceed during regular working hours.