Page 216 - Introduction to chemical reaction engineering and kinetics

P. 216

198 Chapter 8: Catalysis and Catalytic Reactions

the rate is given by

(74) = kKACACB

1 + KAcA + KCCC

Even though the reaction is bimolecular, reactant inhibition does not occur for this type

of reaction.

Variable site characteristics: Sites which have variable properties have been observed.

These have been treated in several ways, including (1) distribution ofsite types, which

can be thought of as equivalent to having a distribution of catalysts operating inde-

pendently; and (2) site properties which change with the presence of other adsorbates,

although they are all the same at a given condition. In the latter case, for example,

the rate constants for adsorption or surface reactions can depend on the amounts of

other adsorbed intermediates: k, = f(6,, 13,, . . . ). An example is the well-studied de-

pendence of the heat of adsorption of CO on various metals, which decreases as the

coverage of the surface by CO increases.

8.5 HETEROGENEOUS CATALYSIS: KINETICS IN POROUS

CATALYST PARTICLES

8.5.1 General Considerations

For a solid-catalyzed gas-phase reaction, the catalyst is commonly in the form of par-

ticles or pellets of various possible shapes and sizes, and formed in various ways. Such

particles are usually porous, and the interior surface accessible to the reacting species

is usually much greater than the gross exterior surface.

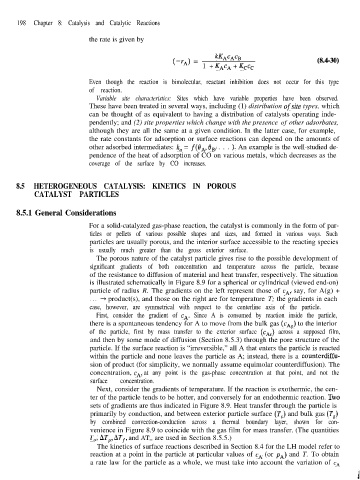

The porous nature of the catalyst particle gives rise to the possible development of

significant gradients of both concentration and temperature across the particle, because

of the resistance to diffusion of material and heat transfer, respectively. The situation

is illustrated schematically in Figure 8.9 for a spherical or cylindrical (viewed end-on)

particle of radius R. The gradients on the left represent those of CA, say, for A(g) +

. . . -+ product(s), and those on the right are for temperature T; the gradients in each

case, however, are symmetrical with respect to the centerline axis of the particle.

First, consider the gradient of CA. Since A is consumed by reaction inside the particle,

there is a spontaneous tendency for A to move from the bulk gas (CA& to the interior

of the particle, first by mass transfer to the exterior surface (c,&) across a supposed film,

and then by some mode of diffusion (Section 8.5.3) through the pore structure of the

particle. If the surface reaction is “irreversible,” all A that enters the particle is reacted

within the particle and none leaves the particle as A; instead, there is a counterdiffu-

sion of product (for simplicity, we normally assume equimolar counterdiffusion). The

concentration, cA, at any point is the gas-phase concentration at that point, and not the

surface concentration.

Next, consider the gradients of temperature. If the reaction is exothermic, the cen-

ter of the particle tends to be hotter, and conversely for an endothermic reaction. lJvo

sets of gradients are thus indicated in Figure 8.9. Heat transfer through the particle is

primarily by conduction, and between exterior particle surface (T,) and bulk gas (T,)

by combined convection-conduction across a thermal boundary layer, shown for con-

venience in Figure 8.9 to coincide with the gas film for mass transfer. (The quantities

To, ATp, ATf, and AT,, are used in Section 8.5.5.)

The kinetics of surface reactions described in Section 8.4 for the LH model refer to

reaction at a point in the particle at particular values of cA (or PA) and T. To obtain

a rate law for the particle as a whole, we must take into account the variation of CA