Page 328 - Introduction to chemical reaction engineering and kinetics

P. 328

v

Reactors 309

and

Semicontinuous

12.4

Semibatch

0 Equation (C) can be solved by trial, or by using an equation solver. For td = 30 min

we obtain t = 45 min using the E-Z Solve software (see file

and kA = 0.021 mm’,

“OF

Then, from equation (A), fA

exl2-6.msp).

= 0.612 for maximum R(C), and from equa-

tion 12.3-22, with nAo = 5 mol, h(C) = 2.45 mol h-l.

12.4 SEMIBATCH AND SEMICONTINUOUS REACTORS

A semibatch reactor is a variation of a batch reactor in which one reactant may be added

intermittently or continuously to another contained as a batch in a vessel, or a product

may be removed intermittently or continuously from the vessel as reaction proceeds.

The reaction may be single-phase or multiphase. As in a batch reactor, the operation

is inherently unsteady-state and usually characterized by a cycle of operation, although

in a more complex manner.

A semicontinuous reactor is a reactor for a multiphase reaction in which one phase

flows continuously through a vessel containing a batch of another phase. The opera-

tion is thus unsteady-state with respect to the batch phase, and may be steady-state

or unsteady-state with respect to the flowing phase, as in a fixed-bed catalytic reactor

(Chapter 21) or a fixed-bed gas-solid reactor (Chapter 22) respectively.

In this section, we consider various modes of operation of these types of reactors,

their advantages and disadvantages, and some design aspects. Since there are many

variations of these reactors, it is difficult to generalize their design or analysis, and con-

sequently we use an example for illustration.

12.4.1 Modes of Operation: Semibatch and Semicontinuous Reactors

12.4.1.1 Semibatch Reactors

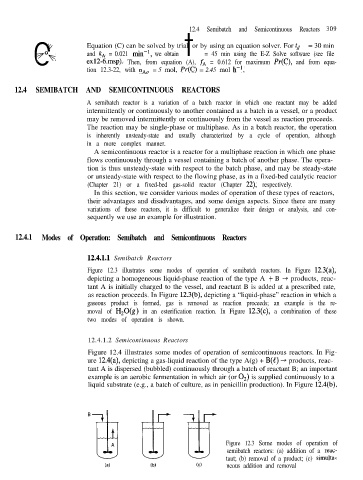

Figure 12.3 illustrates some modes of operation of semibatch reactors. In Figure 12.3(a),

depicting a homogeneous liquid-phase reaction of the type A + B -+ products, reac-

tant A is initially charged to the vessel, and reactant B is added at a prescribed rate,

as reaction proceeds. In Figure 12.3(b), depicting a “liquid-phase” reaction in which a

gaseous product is formed, gas is removed as reaction proceeds; an example is the re-

moval of H,O(g) in an esterification reaction. In Figure 12.3(c), a combination of these

two modes of operation is shown.

12.4.1.2 Semicontinuous Reactors

Figure 12.4 illustrates some modes of operation of semicontinuous reactors. In Fig-

ure 12.4(a), depicting a gas-liquid reaction of the type A(g) + B(e) + products, reac-

tant A is dispersed (bubbled) continuously through a batch of reactant B; an important

example is an aerobic fermentation in which air (or 0,) is supplied continuously to a

liquid substrate (e.g., a batch of culture, as in penicillin production). In Figure 12.4(b),

Figure 12.3 Some modes of operation of

semibatch reactors: (a) addition of a reac-

taut; (b) removal of a product; (c) simulta-

(a) (b) neous addition and removal