Page 36 - Introduction to chemical reaction engineering and kinetics

P. 36

18 Chapter 1: Introduction

1.54 An Example of an Industrial Reactor

One of the most important industrial chemical processes is the manufacture of sulfuric

acid. A major step in this process is the oxidation of SO, with air or oxygen-enriched air

in the reversible, exothermic reaction corresponding to equation (A) in Example 1-2:

so, + ;oz 2 so,

This is carried out in a continuous-flow reactor (“SO, converter”) in several stages, each

stage containing a bed of particles of catalyst (promoted V,O,).

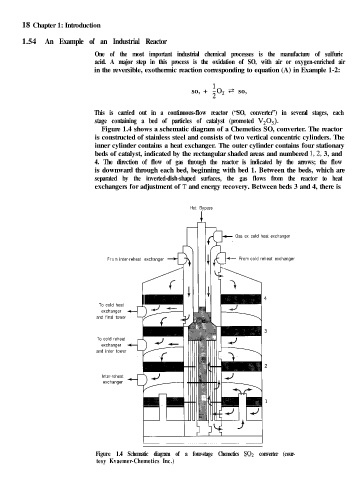

Figure 1.4 shows a schematic diagram of a Chemetics SO, converter. The reactor

is constructed of stainless steel and consists of two vertical concentric cylinders. The

inner cylinder contains a heat exchanger. The outer cylinder contains four stationary

beds of catalyst, indicated by the rectangular shaded areas and numbered 1,2, 3, and

4. The direction of flow of gas through the reactor is indicated by the arrows; the flow

is downward through each bed, beginning with bed 1. Between the beds, which are

separated by the inverted-dish-shaped surfaces, the gas flows from the reactor to heat

exchangers for adjustment of T and energy recovery. Between beds 3 and 4, there is

Hot Bypass

(a- Gas ex cold heat exchanger

F r o m inter-reheat exchanger From cold reheat exchanger

To cold heat J

exchanger

and final tower

To cold reheat

exchanger

and inter tower

Inter-reheat

exchanger

I I

Figure 1.4 Schematic diagram of a four-stage Chemetics SO2 converter (cour-

tesy Kvaemer-Chemetics Inc.)