Page 338 - Sami Franssila Introduction to Microfabrication

P. 338

Tools for Hot Processes 317

Lamp array

Lamp (s)

Reflector Quartz liner Al door

Quartz window

Wafer Water cooled

housing

Quartz pins

Stainless steel Water

Gases out to

vacuum pump Quartz wafer tray

Gases in CaF 2 window

IR pyrometer

Optical pyrometer

(a) (b)

Heater module

Heating section

Heating element

Process chamber

(SiC)

Insulation

Cooling

gas inlet Wafer

Wafer support

(quartz)

Transfer chamber

Gas inlet

(Un)load

arm

Elevator

Servomotor

Pyrometer

(c)

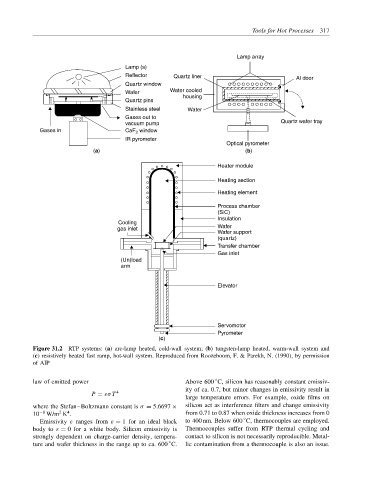

Figure 31.2 RTP systems: (a) arc-lamp heated, cold-wall system; (b) tungsten-lamp heated, warm-wall system and

(c) resistively heated fast ramp, hot-wall system. Reproduced from Roozeboom, F. & Parekh, N. (1990), by permission

of AIP

law of emitted power Above 600 C, silicon has reasonably constant emissiv-

◦

ity of ca. 0.7, but minor changes in emissivity result in

4

P = εσT

large temperature errors. For example, oxide films on

where the Stefan–Boltzmann constant is σ = 5.6697 × silicon act as interference filters and change emissivity

2

4

10 −8 W/m K . from 0.71 to 0.87 when oxide thickness increases from 0

◦

Emissivity ε ranges from ε = 1 for an ideal black to 400 nm. Below 600 C, thermocouples are employed.

body to ε = 0 for a white body. Silicon emissivity is Thermocouples suffer from RTP thermal cycling and

strongly dependent on charge-carrier density, tempera- contact to silicon is not necessarily reproducible. Metal-

ture and wafer thickness in the range up to ca. 600 C. lic contamination from a thermocouple is also an issue.

◦