Page 339 - Sami Franssila Introduction to Microfabrication

P. 339

318 Introduction to Microfabrication

135 251

138 138 245

251 257 257

262

142

145 268

145

142 151

268

145 148 142 262

262

145

142

257 268 268

148 151 273

138 138 279 284

145 142 273 257

135

251 279

132

245 257

129 251 257 245

138 262

129 135 251

132

(a) (b)

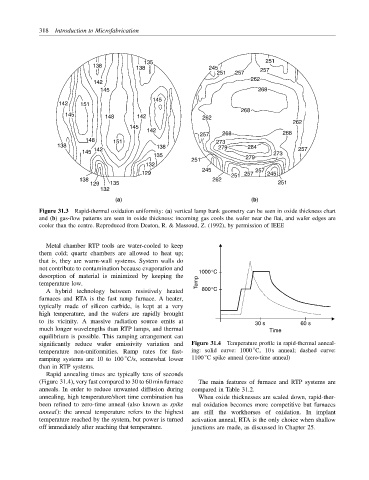

Figure 31.3 Rapid-thermal oxidation uniformity: (a) vertical lamp bank geometry can be seen in oxide thickness chart

and (b) gas-flow patterns are seen in oxide thickness: incoming gas cools the wafer near the flat, and wafer edges are

cooler than the centre. Reproduced from Deaton, R. & Massoud, Z. (1992), by permission of IEEE

Metal chamber RTP tools are water-cooled to keep

them cold; quartz chambers are allowed to heat up;

that is, they are warm-wall systems. System walls do

not contribute to contamination because evaporation and 1000°C

desorption of material is minimized by keeping the

temperature low. Temp

A hybrid technology between resistively heated 800°C

furnaces and RTA is the fast ramp furnace. A heater,

typically made of silicon carbide, is kept at a very

high temperature, and the wafers are rapidly brought

to its vicinity. A massive radiation source emits at 30 s 60 s

much longer wavelengths than RTP lamps, and thermal Time

equilibrium is possible. This ramping arrangement can

significantly reduce wafer emissivity variation and Figure 31.4 Temperature profile in rapid-thermal anneal-

◦

temperature non-uniformities. Ramp rates for fast- ing: solid curve: 1000 C, 10 s anneal; dashed curve:

◦

ramping systems are 10 to 100 C/s, somewhat lower 1100 C spike anneal (zero-time anneal)

◦

than in RTP systems.

Rapid annealing times are typically tens of seconds

(Figure 31.4), very fast compared to 30 to 60 min furnace The main features of furnace and RTP systems are

anneals. In order to reduce unwanted diffusion during compared in Table 31.2.

annealing, high temperature/short time combination has When oxide thicknesses are scaled down, rapid-ther-

been refined to zero-time anneal (also known as spike mal oxidation becomes more competitive but furnaces

anneal): the anneal temperature refers to the highest are still the workhorses of oxidation. In implant

temperature reached by the system, but power is turned activation anneal, RTA is the only choice when shallow

off immediately after reaching that temperature. junctions are made, as discussed in Chapter 25.