Page 239 - Know and Understand Centrifugal Pumps

P. 239

Know and Understand Centrifugal Pumps

damages most seals by blasting the seal with the highest concentration

of solids moving through the pump. As a pump is converted from

packings to mechanical seals, removing the discharge bypass line,

opening the seal chamber bore, and machining the restriction bushing

in the bottom of the chamber will go a long way to achieving the

desired life with a mechanical seal.

Proper pump repair alignment methods

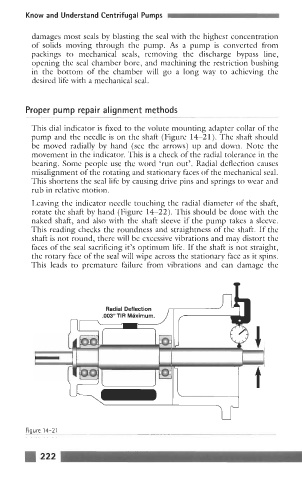

This dial indicator is fixed to the volute mounting adapter collar of the

pump and the needle is on the shaft (Figure 14-21). The shaft should

be moved radially by hand (see the arrows) up and down. Note the

movement in the indicator. This is a check of the radial tolerance in the

bearing. Some people use the word 'run out'. Radial deflection causes

misalignment of the rotating and stationary faces of the mechanical seal.

This shortens the seal life by causing drive pins and springs to wear and

rub in relative motion.

Leaving the indicator needle touching the radial diameter of the shaft,

rotate the shaft by hand (Figure 14-22). This should be done with the

naked shaft, and also with the shaft sleeve if the pump takes a sleeve.

This reading checks the roundness and straightness of the shaft. If the

shaft is not round, there will be excessive vibrations and may distort the

faces of the seal sacrificing it's optimum life. If the shaft is not straight,

the rotary face of the seal will wipe across the stationary face as it spins.

This leads to premature failure from vibrations and can damage the

Radial Deflection

.003" TIR Maximum.

U

Figure 14-21

222