Page 251 - Know and Understand Centrifugal Pumps

P. 251

Know and Understand Centrifugal Pumps

t

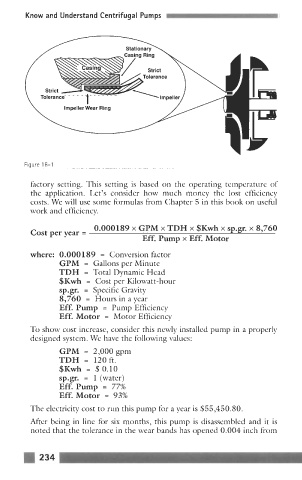

Tolerance

Impeller Wear Ring

factory setting. This setting is based on the operating temperature of

the application. Let’s consider how much money the lost efficiency

costs. We will use some formulas from Chapter 5 in this book on useful

work and efficiency.

0.000189 x GPM x TDH x $Kwh x sp.gr. x 8,760

Cost per year =

Eff. Pump x Eff. Motor

where: 0.000189 = Conversion factor

GPM = Gallons per Minute

TDH = Total Dynamic Head

$Kwh = Cost per Kilowatt-hour

sp.gr. = Specific Gravity

8,760 = Hours in a year

Eff. Pump = Pump Efficiency

Eff. Motor = Motor Efficiency

To show cost increase, consider this newly installed pump in a properly

designed system. We have the following values:

GPM = 2,000gpm

TDH = 120ft.

$Kwh = $0.10

sp.gr. = 1 (water)

Eff. Pump = 77%

Eff. Motor = 93%

The electricity cost to run this pump for a year is $55,450.80.

Mer being in line for six months, this pump is disassembled and it is

noted that the tolerance in the wear bands has opened 0.004 inch from

234