Page 253 - Know and Understand Centrifugal Pumps

P. 253

Know and Understand Centrifugal Pumps

SUCTION

BEARING

DOUBLE SUCTION

ATTHE

E OF THIS

PUMP

RESS

IN THE BEARINGS

AND WEAR RINGS

MOTOR

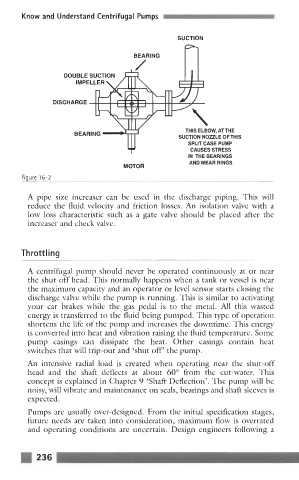

Fiaure 16-2

A pipe size increaser can be used in the discharge piping. This will

reduce the fluid velocity and friction losses. An isolation valve with a

low loss characteristic such as a gate valve should be placed after the

increaser and check valve.

Th rott I i ng

A centrifugal pump should never be operated continuously at or near

the shut off head. This normally happens when a tank or vessel is near

the maximum capacity and an operator or level sensor starts closing the

discharge valve while the pump is running. This is similar to activating

your car brakes while the gas pedal is to the metal. All this wasted

energy is transferred to the fluid being pumped. This type of operation

shortens the life of the pump and increases the downtime. This energy

is converted into heat and vibration raising the fluid temperature. Some

pump casings can dissipate the heat. Other casings contain heat

switches that will trip-out and 'shut off the pump.

An intensive radial load is created when operating near the shut-off

head and the shaft deflects at about 60" from the cut-water. This

concept is explained in Chapter 9 'Shaft Deflection'. The pump will be

noisy, will vibrate and maintenance on seals, bearings and shaft sleeves is

expected.

Pumps are usually over-designed. From the initial specification stages,

future needs are taken into consideration, maximum flow is overrated

and operating conditions are uncertain. Design engineers following a