Page 116 - Materials Chemistry, Second Edition

P. 116

102 K. T. Lee and C. Ofori-Boateng

Air FFB

Water Emissions

S

BOILER STERILIZER

Landfills

EFB

Fibre and kernel

STRIPPER

Mulch

S DIGESTER

Shells & fibre

Pressed cake & nuts

SCREW PRESS

SEPARATOR

Pressed liquor

VIBRATING SCREEN

DRYER

Oil

CLARIFIER

NUT CRACKER

Sludge Oil

DESILTER PURIFIER CYCLONE

Nuts

SEPARATOR PURIFIER

HYDROCYCLONE

Sludge CPO

DRYER

Palm kernel

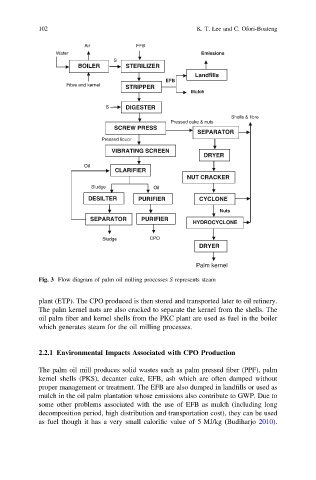

Fig. 3 Flow diagram of palm oil milling processes S represents steam

plant (ETP). The CPO produced is then stored and transported later to oil refinery.

The palm kernel nuts are also cracked to separate the kernel from the shells. The

oil palm fiber and kernel shells from the PKC plant are used as fuel in the boiler

which generates steam for the oil milling processes.

2.2.1 Environmental Impacts Associated with CPO Production

The palm oil mill produces solid wastes such as palm pressed fiber (PPF), palm

kernel shells (PKS), decanter cake, EFB, ash which are often damped without

proper management or treatment. The EFB are also dumped in landfills or used as

mulch in the oil palm plantation whose emissions also contribute to GWP. Due to

some other problems associated with the use of EFB as mulch (including long

decomposition period, high distribution and transportation cost), they can be used

as fuel though it has a very small calorific value of 5 MJ/kg (Budiharjo 2010).