Page 118 - Materials Chemistry, Second Edition

P. 118

104 K. T. Lee and C. Ofori-Boateng

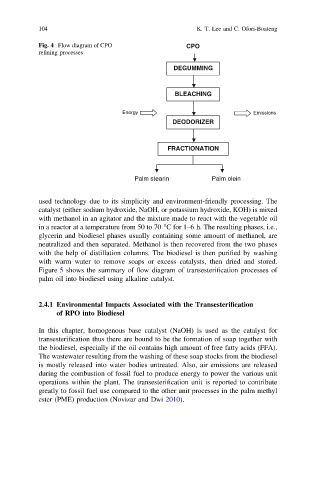

Fig. 4 Flow diagram of CPO CPO

refining processes

DEGUMMING

BLEACHING

Energy Emissions

DEODORIZER

FRACTIONATION

Palm stearin Palm olein

used technology due to its simplicity and environment-friendly processing. The

catalyst (either sodium hydroxide, NaOH, or potassium hydroxide, KOH) is mixed

with methanol in an agitator and the mixture made to react with the vegetable oil

in a reactor at a temperature from 50 to 70 °C for 1–6 h. The resulting phases, i.e.,

glycerin and biodiesel phases usually containing some amount of methanol, are

neutralized and then separated. Methanol is then recovered from the two phases

with the help of distillation columns. The biodiesel is then purified by washing

with warm water to remove soaps or excess catalysts, then dried and stored.

Figure 5 shows the summary of flow diagram of transesterification processes of

palm oil into biodiesel using alkaline catalyst.

2.4.1 Environmental Impacts Associated with the Transesterification

of RPO into Biodiesel

In this chapter, homogenous base catalyst (NaOH) is used as the catalyst for

transesterification thus there are bound to be the formation of soap together with

the biodiesel, especially if the oil contains high amount of free fatty acids (FFA).

The wastewater resulting from the washing of these soap stocks from the biodiesel

is mostly released into water bodies untreated. Also, air emissions are released

during the combustion of fossil fuel to produce energy to power the various unit

operations within the plant. The transesterification unit is reported to contribute

greatly to fossil fuel use compared to the other unit processes in the palm methyl

ester (PME) production (Novizar and Dwi 2010).