Page 149 - Materials Chemistry, Second Edition

P. 149

136 S. H. Gheewala

for example, greenhouse gases are aggregated into global warming potential

represented in terms of kg CO 2 eq instead of evaluating the final damage due to

climate change. The midpoint approach reduces the uncertainty introduced from

complex modeling approaches as well as forecasting and effect modeling

(Blottnitz and Curran 2007). Similar to the case for global warming, the other

impact categories of interest are acidification (kg SO 2 eq), eutrophication

3-

(kg PO 4 eq), and human toxicity (kg 1,4 DCBeq).

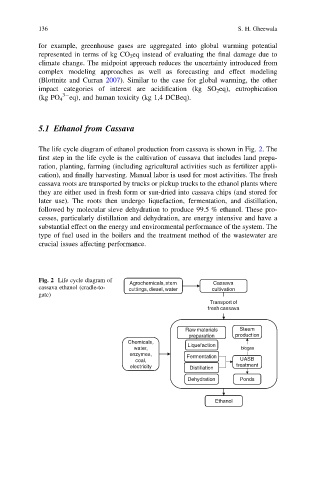

5.1 Ethanol from Cassava

The life cycle diagram of ethanol production from cassava is shown in Fig. 2. The

first step in the life cycle is the cultivation of cassava that includes land prepa-

ration, planting, farming (including agricultural activities such as fertilizer appli-

cation), and finally harvesting. Manual labor is used for most activities. The fresh

cassava roots are transported by trucks or pickup trucks to the ethanol plants where

they are either used in fresh form or sun-dried into cassava chips (and stored for

later use). The roots then undergo liquefaction, fermentation, and distillation,

followed by molecular sieve dehydration to produce 99.5 % ethanol. These pro-

cesses, particularly distillation and dehydration, are energy intensive and have a

substantial effect on the energy and environmental performance of the system. The

type of fuel used in the boilers and the treatment method of the wastewater are

crucial issues affecting performance.

Fig. 2 Life cycle diagram of

Agrochemicals, stem Cassava

cassava ethanol (cradle-to- cuttings, diesel, water cultivation

gate)

Transport of

fresh cassava

Raw materials Steam

preparation production

Chemicals, Liquefaction

water, biogas

enzymes, Fermentation

coal, UASB

electricity Distillation treatment

Dehydration Ponds

Ethanol