Page 154 - Materials Chemistry, Second Edition

P. 154

Environmental Sustainability Assessment of Ethanol 141

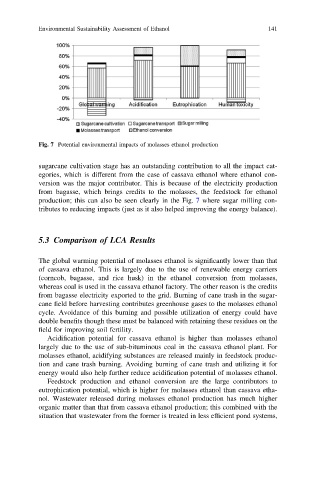

Fig. 7 Potential environmental impacts of molasses ethanol production

sugarcane cultivation stage has an outstanding contribution to all the impact cat-

egories, which is different from the case of cassava ethanol where ethanol con-

version was the major contributor. This is because of the electricity production

from bagasse, which brings credits to the molasses, the feedstock for ethanol

production; this can also be seen clearly in the Fig. 7 where sugar milling con-

tributes to reducing impacts (just as it also helped improving the energy balance).

5.3 Comparison of LCA Results

The global warming potential of molasses ethanol is significantly lower than that

of cassava ethanol. This is largely due to the use of renewable energy carriers

(corncob, bagasse, and rice husk) in the ethanol conversion from molasses,

whereas coal is used in the cassava ethanol factory. The other reason is the credits

from bagasse electricity exported to the grid. Burning of cane trash in the sugar-

cane field before harvesting contributes greenhouse gases to the molasses ethanol

cycle. Avoidance of this burning and possible utilization of energy could have

double benefits though these must be balanced with retaining these residues on the

field for improving soil fertility.

Acidification potential for cassava ethanol is higher than molasses ethanol

largely due to the use of sub-bituminous coal in the cassava ethanol plant. For

molasses ethanol, acidifying substances are released mainly in feedstock produc-

tion and cane trash burning. Avoiding burning of cane trash and utilizing it for

energy would also help further reduce acidification potential of molasses ethanol.

Feedstock production and ethanol conversion are the large contributors to

eutrophication potential, which is higher for molasses ethanol than cassava etha-

nol. Wastewater released during molasses ethanol production has much higher

organic matter than that from cassava ethanol production; this combined with the

situation that wastewater from the former is treated in less efficient pond systems,