Page 269 - Materials Chemistry, Second Edition

P. 269

Hydropower Life-Cycle Inventories 259

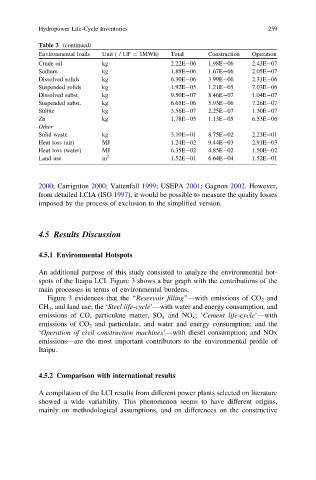

Table 3 (continued)

Environmental loads Unit ( / UF = 1MWh) Total Construction Operation

Crude oil kg 2.22E-06 1.98E-06 2.43E-07

Sodium kg 1.88E-06 1.67E-06 2.05E-07

Dissolved solids kg 6.30E-06 3.99E-06 2.31E-06

Suspended solids kg 1.92E-05 1.21E-05 7.03E-06

Dissolved subst. kg 9.50E-07 8.46E-07 1.04E-07

Suspended subst. kg 6.65E-06 5.93E-06 7.26E-07

Sulfite kg 3.56E-07 2.25E-07 1.30E-07

Zn kg 1.78E-05 1.13E-05 6.53E-06

Other

Solid waste kg 3.10E-01 8.75E-02 2.23E-01

Heat loss (air) MJ 1.24E-02 9.44E-03 2.91E-03

Heat loss (water) MJ 6.35E-02 4.85E-02 1.50E-02

2

Land use m 1.52E-01 6.64E-04 1.52E-01

2000; Carrignton 2000; Vattenfall 1999; USEPA 2001; Gagnon 2002. However,

from detailed LCIA (ISO 1997), it would be possible to measure the quality losses

imposed by the process of exclusion to the simplified version.

4.5 Results Discussion

4.5.1 Environmental Hotspots

An additional purpose of this study consisted to analyze the environmental hot-

spots of the Itaipu LCI. Figure 3 shows a bar graph with the contributions of the

main processes in terms of environmental burdens.

Figure 3 evidences that the ‘‘Reservoir filling’’—with emissions of CO 2 and

CH 4 , and land use; the ‘Steel life-cycle’—with water and energy consumption, and

emissions of CO, particulate matter, SO x and NO x ;‘Cement life-cycle’—with

emissions of CO 2 and particulate, and water and energy consumption; and the

‘Operation of civil construction machines’—with diesel consumption; and NOx

emissions—are the most important contributors to the environmental profile of

Itaipu.

4.5.2 Comparison with international results

A compilation of the LCI results from different power plants selected on literature

showed a wide variability. This phenomenon seems to have different origins,

mainly on methodological assumptions, and on differences on the constructive