Page 164 - Lignocellulosic Biomass to Liquid Biofuels

P. 164

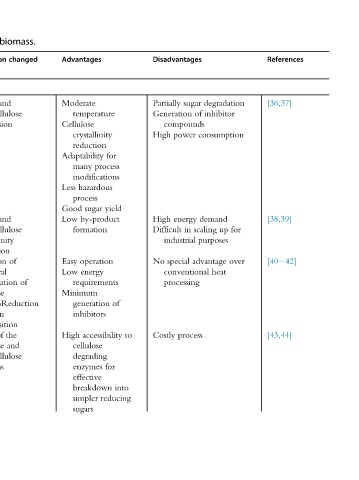

References [36,37] [38,39] [40 42] [43,44]

degradation inhibitor consumption demand for up scaling purposes over advantage heat

Disadvantages sugar Partially of Generation compounds power High energy High in Difficult industrial special No conventional processing process Costly

to for into reducing

yield

process

of

for

Advantages Moderate temperature Cellulose crystallinity reduction Adaptability many modifications hazardous Less process sugar Good by-product Low formation operation Easy energy Low requirements Minimum generation inhibitors accessibility High cellulose degrading enzymes effective breakdown simpler

biomass. changed of of fractionReduction the and

of Composition and Cellulose hemicellulose conversion and Cellulose hemicellulose crystallinity disruption Degradation structural organization cellulose lignin in composition of Rupture cellulose hemicellulose fractions

pretreatment

the under H 3 PO 4

for grinding, process mixing,

used Procedure Chipping, milling Heating shear T . 300°C 1% 5%NaOH, 4 30 min 300 600 W Sonication 10 100 kHz

processes 50°C

various corn straw, wheat cane sweet sorghum bagasse stover, switchgrass, soybean stover, sugarcane rape bagasse, Miscanthus corn bagasse, switchgrass, Sorghum,

of Feedstock Rice stover, straw, and Corn Switchgrass, corn straw, Sugarcane stover, poplar

Summary size

4.2 reduction extrusion

Table Pretreatment process Physical Mechanical Mechanical Microwave Ultrasound