Page 168 - Lignocellulosic Biomass to Liquid Biofuels

P. 168

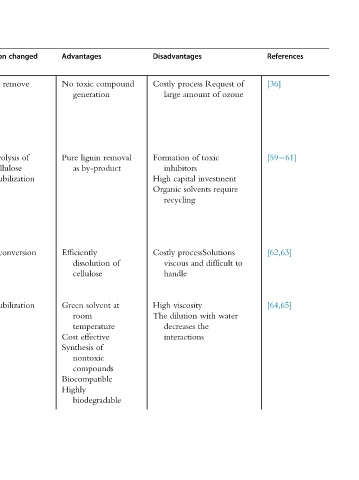

References [36] [59 61] [62,63] [64,65]

of ozone to

Request of toxic investment require processSolutions difficult water with the

Disadvantages process Costly amount large of Formation inhibitors capital High solvents Organic recycling Costly and viscous handle viscosity High dilution The decreases interactions

compound removal by-product of at solvent of

Advantages toxic No generation lignin Pure as Efficiently dissolution cellulose Green room temperature effective Cost Synthesis nontoxic compounds Biocompatible Highly biodegradable

changed remove of solubilization conversion solubilization

Composition Effectively lignin hydrolysis Total hemicellulose Lignin Cellulose Lignin

or min,

and ethanol, ethylene triethylene mixture H 2 SO 4 30 60 20:1 to 30 min sugars, and organic

room temperature, solvents (methanol, or of 1% pH 5 2.0 3.4 liquid/biomass equal urea, acids, other

Procedure Ozone, pressure Organic acetone, glycol, glycol) with HCl T 5 185°C, Ionic ratio T 5 120°C, Choline, amino several acids

straw, hay, straw, sugarcane pine straw, and stover straw

Feedstock Wheat bagasse, peanut, poplar, sawdust, green pine Wheat bagasse, poplar, spruce, Wheat bagasse, peanut, poplar corn Rice

(Continued)

4.2 liquids deep eutectic solvents

Table Pretreatment process Ozonolysis Organosolv Ionic Natural