Page 166 - Lignocellulosic Biomass to Liquid Biofuels

P. 166

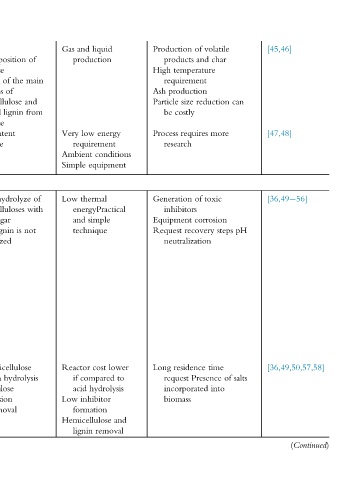

[45,46] [47,48] [36,49 56] [36,49,50,57,58] (Continued)

can pH salts of

volatile char reduction more toxic corrosion steps time into

of and temperature requirement production size requires of recovery neutralization residence Presence incorporated

Production products High Ash Particle costly be Process research Generation inhibitors Equipment Request Long request biomass

liquid energy requirement conditions equipment thermal energyPractical simple lower cost to compared hydrolysis inhibitor and removal

and production low Ambient and technique Reactor if acid formation Hemicellulose lignin

Gas Very Simple Low Low

main from of with

of the and not is hydrolysis

decomposition of of hemicellulose lignin content hydrolyze hemicelluloses sugar yieldLignin solubilized hemicellulose cellulose conversion removal

Thermal cellulose Separation portions residual cellulose Lignin decrease Effective high High fraction High Lignin

cooling kV/ duration milliseconds) H 2 SO 4 ,HCl, for (5% high ratio 60°C, 4 h 35° v/v),

then condensing (5 20 short to process loads solids substrate/ for (10% 40% substrate/mixture) H 2 SO 4 Solid/Liquid NaOH, 120°C, H 2 O 2

T . 300°C, and voltage High for cm) (nano (Dilute) 0.75% 5% HNO 3 T 5 160°C 200°C P 5 1 MPa Continuous low 10% mixture) process Batch loads (Concentrated) 10% 30% T 5 170°C 190°C 1:2 Dilute h 24 Ca(OH) 2 , of Adding (0.5 2.15% C

waste corn switchgrass chip, switchgrass wood corn bagasse, wheat rye rice switchgrass corn bagasse, cane

Wood, cotton, stover, Wood Poplar stover, straw, straw, hulls, Hardwood, stover, leaves

electric hydrolysis hydrolysis

Pyrolysis Pulsed field Chemical Acid Alkaline