Page 170 - Lignocellulosic Biomass to Liquid Biofuels

P. 170

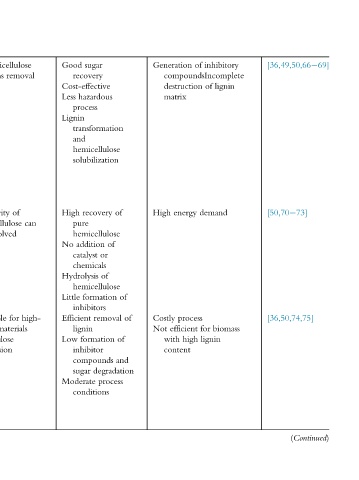

[36,49,50,66 69] [50,70 73] [36,50,74,75] (Continued)

inhibitory lignin demand biomass lignin

of compoundsIncomplete of energy process for high

Generation destruction matrix High Costly efficient Not with content

of of and degradation

of

of

of

sugar recovery Cost-effective hazardous process transformation hemicellulose solubilization recovery hemicellulose addition or catalyst chemicals of hemicellulose formation inhibitors removal lignin formation inhibitor compounds process conditions

Good Less Lignin and High pure No Hydrolysis Little Efficient Low sugar Moderate

hemicellulose removal of majority can hemicellulose dissolved high- for suitable materials cellulose conversion

High fractions The be Not lignin High dry

steam (T 5 160°C 290°C, P 5 .69 4.85 atm, then min), until decompression pressure water hot (T 5 170°C 230°C, P . 5 MPa, min) P 5 1.12 1.36 MPa, ammonia/kg

Saturated 1 10 atmosphere Pressurized 1 46 T 5 90°C, min 30 1 2 kg biomass

straw, stalk, eucalyptus softwood, straw, straw, sorghum olive bagasse, common corn bagasse, wheat sunflower bagasse, stover, pulp straw, stover, straw, wood bagasse, hulls, stover, switchgrass, Bermuda

Wheat corn poplar, aspen, rice barley sweet stones, reed Sugarcane stover, straw, stalk, corn olive Wheat corn rice aspen chips rice corn coastal grass

Physical chemical explosion Steam LHW AFEX