Page 212 - Lignocellulosic Biomass to Liquid Biofuels

P. 212

Biobutanol from lignocellulosic biomass: bioprocess strategies 175

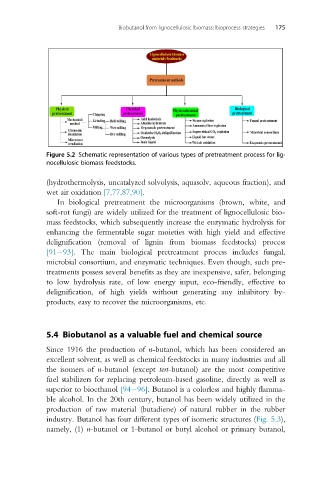

Figure 5.2 Schematic representation of various types of pretreatment process for lig-

nocellulosic biomass feedstocks.

(hydrothermolysis, uncatalyzed solvolysis, aquasolv, aqueous fraction), and

wet air oxidation [7,77,87,90].

In biological pretreatment the microorganisms (brown, white, and

soft-rot fungi) are widely utilized for the treatment of lignocellulosic bio-

mass feedstocks, which subsequently increase the enzymatic hydrolysis for

enhancing the fermentable sugar moieties with high yield and effective

delignification (removal of lignin from biomass feedstocks) process

[91 93]. The main biological pretreatment process includes fungal,

microbial consortium, and enzymatic techniques. Even though, such pre-

treatments possess several benefits as they are inexpensive, safer, belonging

to low hydrolysis rate, of low energy input, eco-friendly, effective to

delignification, of high yields without generating any inhibitory by-

products, easy to recover the microorganisms, etc.

5.4 Biobutanol as a valuable fuel and chemical source

Since 1916 the production of n-butanol, which has been considered an

excellent solvent, as well as chemical feedstocks in many industries and all

the isomers of n-butanol (except tert-butanol) are the most competitive

fuel stabilizers for replacing petroleum-based gasoline, directly as well as

superior to bioethanol [94 96]. Butanol is a colorless and highly flamma-

ble alcohol. In the 20th century, butanol has been widely utilized in the

production of raw material (butadiene) of natural rubber in the rubber

industry. Butanol has four different types of isomeric structures (Fig. 5.3),

namely, (1) n-butanol or 1-butanol or butyl alcohol or primary butanol,