Page 263 - Lignocellulosic Biomass to Liquid Biofuels

P. 263

Fischer Tropsch synthesis of syngas to liquid hydrocarbons 219

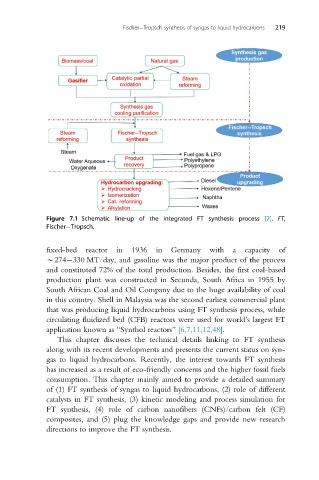

Figure 7.1 Schematic line-up of the integrated FT synthesis process [2]. FT,

Fischer Tropsch.

fixed-bed reactor in 1936 in Germany with a capacity of

B274 330 MT/day, and gasoline was the major product of the process

and constituted 72% of the total production. Besides, the first coal-based

production plant was constructed in Secunda, South Africa in 1955 by

South African Coal and Oil Company due to the huge availability of coal

in this country. Shell in Malaysia was the second earliest commercial plant

that was producing liquid hydrocarbons using FT synthesis process, while

circulating fluidized bed (CFB) reactors were used for world’s largest FT

application known as “Synthol reactors” [6,7,11,12,48].

This chapter discusses the technical details linking to FT synthesis

along with its recent developments and presents the current status on syn-

gas to liquid hydrocarbons. Recently, the interest towards FT synthesis

has increased as a result of eco-friendly concerns and the higher fossil fuels

consumption. This chapter mainly aimed to provide a detailed summary

of (1) FT synthesis of syngas to liquid hydrocarbons, (2) role of different

catalysts in FT synthesis, (3) kinetic modeling and process simulation for

FT synthesis, (4) role of carbon nanofibers (CNFs)/carbon felt (CF)

composites, and (5) plug the knowledge gaps and provide new research

directions to improve the FT synthesis.