Page 132 - Lindens Handbook of Batteries

P. 132

BATTERY DESIGN 5.9

To minimize the possibility of physically reversing a battery, the proper battery orientation should

be clearly marked on the device, with simple and clear instructions. Blind battery compartments,

where the individual batteries are not visible, should be avoided. The best practice is to use oriented

or polarized battery holders, as discussed previously.

A suggested approach is to design the cell cavities for single cells so there are no strings of cells

that could allow an incorrect reversal insertion of one cell. This does add cost to the device by requir-

ing additional contacts, but it ensures that the circuit is correctly completed (by virtue of the physical

connection of the cells by the device’s circuit). Such a design is strongly suggested when a device

can accept primary and rechargeable cells of a particular size, such as the AA or AAA sizes, which

are commonly available in primary alkaline, rechargeable nickel, or primary lithium.

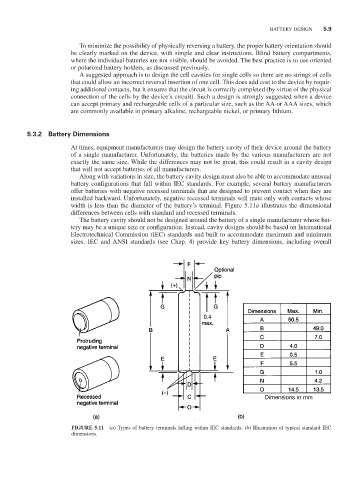

5.3.2 Battery Dimensions

At times, equipment manufacturers may design the battery cavity of their device around the battery

of a single manufacturer. Unfortunately, the batteries made by the various manufacturers are not

exactly the same size. While the differences may not be great, this could result in a cavity design

that will not accept batteries of all manufacturers.

Along with variations in size, the battery cavity design must also be able to accommodate unusual

battery configurations that fall within IEC standards. For example, several battery manufacturers

offer batteries with negative recessed terminals that are designed to prevent contact when they are

installed backward. Unfortunately, negative recessed terminals will mate only with contacts whose

width is less than the diameter of the battery’s terminal. Figure 5.11a illustrates the dimensional

differences between cells with standard and recessed terminals.

The battery cavity should not be designed around the battery of a single manufacturer whose bat-

tery may be a unique size or configuration. Instead, cavity designs should be based on International

Electrotechnical Commission (IEC) standards and built to accommodate maximum and minimum

sizes. IEC and ANSI standards (see Chap. 4) provide key battery dimensions, including overall

FIGURE 5.11 (a) Types of battery terminals falling within IEC standards. (b) Illustration of typical standard IEC

dimensions.