Page 137 - Lindens Handbook of Batteries

P. 137

5.14 PRINCIPLES OF OPERATION

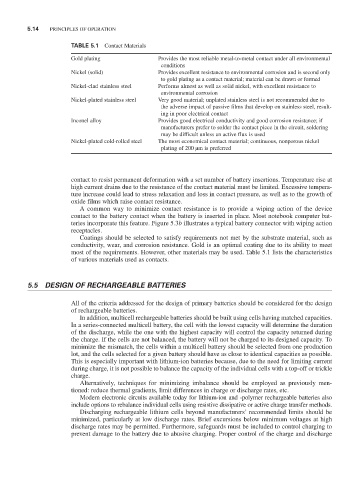

TABLE 5.1 Contact Materials

Gold plating Provides the most reliable metal-to-metal contact under all environmental

conditions

Nickel (solid) Provides excellent resistance to environmental corrosion and is second only

to gold plating as a contact material; material can be drawn or formed

Nickel-clad stainless steel Performs almost as well as solid nickel, with excellent resistance to

environmental corrosion

Nickel-plated stainless steel Very good material; unplated stainless steel is not recommended due to

the adverse impact of passive films that develop on stainless steel, result-

ing in poor electrical contact

Inconel alloy Provides good electrical conductivity and good corrosion resistance; if

manufacturers prefer to solder the contact piece in the circuit, soldering

may be difficult unless an active flux is used

Nickel-plated cold-rolled steel The most economical contact material; continuous, nonporous nickel

plating of 200 µm is preferred

contact to resist permanent deformation with a set number of battery insertions. Temperature rise at

high current drains due to the resistance of the contact material must be limited. Excessive tempera-

ture increase could lead to stress relaxation and loss in contact pressure, as well as to the growth of

oxide films which raise contact resistance.

A common way to minimize contact resistance is to provide a wiping action of the device

contact to the battery contact when the battery is inserted in place. Most notebook computer bat-

teries incorporate this feature. Figure 5.3b illustrates a typical battery connector with wiping action

receptacles.

Coatings should be selected to satisfy requirements not met by the substrate material, such as

conductivity, wear, and corrosion resistance. Gold is an optimal coating due to its ability to meet

most of the requirements. However, other materials may be used. Table 5.1 lists the characteristics

of various materials used as contacts.

5.5 DESIGN OF RECHARGEABLE BATTERIES

All of the criteria addressed for the design of primary batteries should be considered for the design

of rechargeable batteries.

In addition, multicell rechargeable batteries should be built using cells having matched capacities.

In a series-connected multicell battery, the cell with the lowest capacity will determine the duration

of the discharge, while the one with the highest capacity will control the capacity returned during

the charge. If the cells are not balanced, the battery will not be charged to its designed capacity. To

minimize the mismatch, the cells within a multicell battery should be selected from one production

lot, and the cells selected for a given battery should have as close to identical capacities as possible.

This is especially important with lithium-ion batteries because, due to the need for limiting current

during charge, it is not possible to balance the capacity of the individual cells with a top-off or trickle

charge.

Alternatively, techniques for minimizing imbalance should be employed as previously men-

tioned: reduce thermal gradients, limit differences in charge or discharge rates, etc.

Modern electronic circuits available today for lithium-ion and -polymer rechargeable batteries also

include options to rebalance individual cells using resistive dissipative or active charge transfer methods.

Discharging rechargeable lithium cells beyond manufacturers’ recommended limits should be

minimized, particularly at low discharge rates. Brief excursions below minimum voltages at high

discharge rates may be permitted. Furthermore, safeguards must be included to control charging to

prevent damage to the battery due to abusive charging. Proper control of the charge and discharge