Page 252 - Lindens Handbook of Batteries

P. 252

10.4 priMAry bATTerieS

10.2.1 Aluminum

The standard potential for aluminum in the anode reaction,

3+

Al → Al + 3e

is reported as -1.7 V. A battery with an aluminum anode should have a voltage about 0.9 V higher

than the corresponding zinc battery. However, this voltage is not attained, and the voltage of an Al/

MnO battery is only about 0.1 to 0.2 V higher than that of a zinc battery. The Al/MnO battery

2

2

never progressed beyond the experimental stage because of the problems with the oxide film, exces-

sive corrosion when the film was broken, voltage delay, and the tendency for aluminum to corrode

unevenly. The experimental batteries that were fabricated used a two-layer aluminum anode (to

minimize premature failure due to can perforation), an electrolyte of aluminum or chromium chlo-

ride, and a manganese dioxide-acetylene black cathode similar to the conventional zinc/manganese

dioxide battery. The reaction mechanism is

Al + 3MnO + 3H O → 3MnO · OH + Al(OH) 3

2

2

10.3 CONSTRUCTION OF Mg/MnO BATTERIES

2

Magnesium/manganese dioxide (nonreserve) primary batteries are generally constructed in a cylin-

drical configuration.

10.3.1 Standard Construction

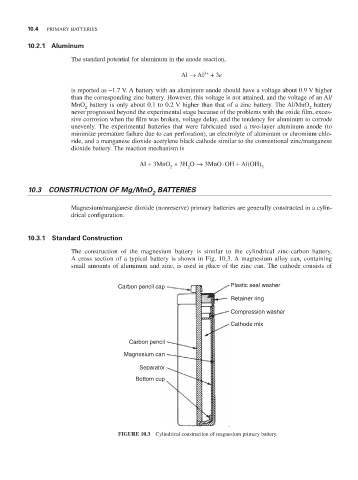

The construction of the magnesium battery is similar to the cylindrical zinc-carbon battery.

A cross section of a typical battery is shown in Fig. 10.3. A magnesium alloy can, containing

small amounts of aluminum and zinc, is used in place of the zinc can. The cathode consists of

Carbon pencil cap Plastic seal washer

Retainer ring

Compression washer

Cathode mix

Carbon pencil

Magnesium can

Separator

Bottom cup

FIGURE 10.3 Cylindrical construction of magnesium primary battery.