Page 253 - Lindens Handbook of Batteries

P. 253

MAGNeSiUM AND ALUMiNUM bATTerieS 10.5

an extruded mix of manganese dioxide, acetylene black for conductivity and moisture retention,

barium chromate (an inhibitor), and magnesium hydroxide (a pH buffer). The electrolyte is an

aqueous solution of magnesium perchlorate with lithium chromate. A carbon rod serves as the

cathode current collector. The separator is an absorbent kraft paper as in the paper-lined zinc

battery structure. Sealing of the magnesium battery is critical, as it must be tight to retain bat-

tery moisture during storage but provide a means for the escape of hydrogen gas which forms as

the result of the corrosion reaction during the discharge. This is accomplished by a mechanical

vent—a small hole in the plastic top seal washer under the retainer ring which is deformed under

pressure, releasing the excess gas. 8

10.3.2 Inside-Out Construction

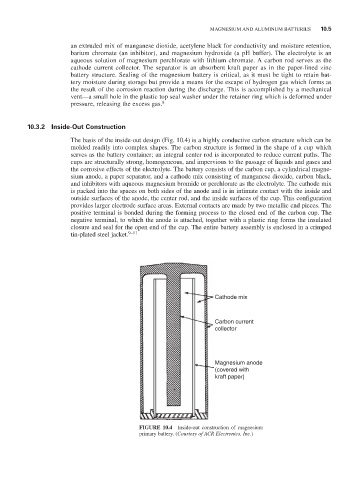

The basis of the inside-out design (Fig. 10.4) is a highly conductive carbon structure which can be

molded readily into complex shapes. The carbon structure is formed in the shape of a cup which

serves as the battery container; an integral center rod is incorporated to reduce current paths. The

cups are structurally strong, homogeneous, and impervious to the passage of liquids and gases and

the corrosive effects of the electrolyte. The battery consists of the carbon cup, a cylindrical magne-

sium anode, a paper separator, and a cathode mix consisting of manganese dioxide, carbon black,

and inhibitors with aqueous magnesium bromide or perchlorate as the electrolyte. The cathode mix

is packed into the spaces on both sides of the anode and is in intimate contact with the inside and

outside surfaces of the anode, the center rod, and the inside surfaces of the cup. This configuration

provides larger electrode surface areas. external contacts are made by two metallic end pieces. The

positive terminal is bonded during the forming process to the closed end of the carbon cup. The

negative terminal, to which the anode is attached, together with a plastic ring forms the insulated

closure and seal for the open end of the cup. The entire battery assembly is enclosed in a crimped

tin-plated steel jacket. 9–11

Cathode mix

Carbon current

collector

Magnesium anode

(covered with

kraft paper)

FIGURE 10.4 inside-out construction of magnesium

primary battery. (Courtesy of ACR Electronics, Inc.)