Page 277 - Lindens Handbook of Batteries

P. 277

ALKALINE-MANGANESE DIOXIDE BATTERIES 11.15

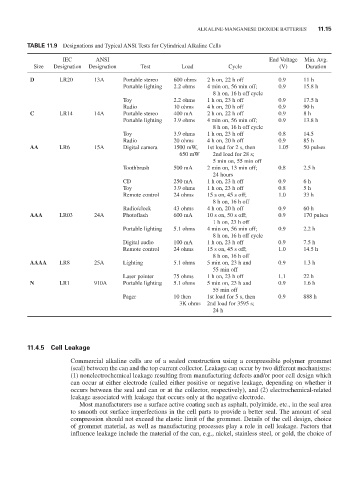

TABLE 11.9 Designations and Typical ANSI Tests for Cylindrical Alkaline Cells

IEC ANSI End Voltage Min. Avg.

Size Designation Designation Test Load Cycle (V) Duration

D LR20 13A portable stereo 600 ohms 2 h on, 22 h off 0.9 11 h

portable lighting 2.2 ohms 4 min on, 56 min off; 0.9 15.8 h

8 h on, 16 h off cycle

Toy 2.2 ohms 1 h on, 23 h off 0.9 17.5 h

Radio 10 ohms 4 h on, 20 h off 0.9 90 h

C LR14 14A portable stereo 400 mA 2 h on, 22 h off 0.9 8 h

portable lighting 3.9 ohms 4 min on, 56 min off; 0.9 13.8 h

8 h on, 16 h off cycle

Toy 3.9 ohms 1 h on, 23 h off 0.8 14.5

Radio 20 ohms 4 h on, 20 h off 0.9 85 h

AA LR6 15A Digital camera 1500 mW, 1st load for 2 s, then 1.05 50 pulses

650 mW 2nd load for 28 s;

5 min on, 55 min off

Toothbrush 500 mA 2 min on, 13 min off; 0.8 2.5 h

24 hours

CD 250 mA 1 h on, 23 h off 0.9 6 h

Toy 3.9 ohms 1 h on, 23 h off 0.8 5 h

Remote control 24 ohms 15 s on, 45 s off; 1.0 33 h

8 h on, 16 h off

Radio/clock 43 ohms 4 h on, 20 h off 0.9 60 h

AAA LR03 24A photoflash 600 mA 10 s on, 50 s off; 0.9 170 pulses

1 h on, 23 h off

portable lighting 5.1 ohms 4 min on, 56 min off; 0.9 2.2 h

8 h on, 16 h off cycle

Digital audio 100 mA 1 h on, 23 h off 0.9 7.5 h

Remote control 24 ohms 15 s on, 45 s off; 1.0 14.5 h

8 h on, 16 h off

AAAA LR8 25A Lighting 5.1 ohms 5 min on, 23 h and 0.9 1.3 h

55 min off

Laser pointer 75 ohms 1 h on, 23 h off 1.1 22 h

N LR1 910A portable lighting 5.1 ohms 5 min on, 23 h and 0.9 1.6 h

55 min off

pager 10 then 1st load for 5 s, then 0.9 888 h

3K ohms 2nd load for 3595 s;

24 h

11.4.5 Cell Leakage

Commercial alkaline cells are of a sealed construction using a compressible polymer grommet

(seal) between the can and the top current collector. Leakage can occur by two different mechanisms:

(1) nonelectrochemical leakage resulting from manufacturing defects and/or poor cell design which

can occur at either electrode (called either positive or negative leakage, depending on whether it

occurs between the seal and can or at the collector, respectively), and (2) electrochemical-related

leakage associated with leakage that occurs only at the negative electrode.

Most manufacturers use a surface active coating such as asphalt, polyimide, etc., in the seal area

to smooth out surface imperfections in the cell parts to provide a better seal. The amount of seal

compression should not exceed the elastic limit of the grommet. Details of the cell design, choice

of grommet material, as well as manufacturing processes play a role in cell leakage. Factors that

influence leakage include the material of the can, e.g., nickel, stainless steel, or gold, the choice of