Page 273 - Lindens Handbook of Batteries

P. 273

ALKALINE-MANGANESE DIOXIDE BATTERIES 11.11

the cathode-to-can contact. Such a treatment of the steel could be a nickel plating or coating with a

conductive carbon paint. Such treatments are typically for those cells used specifically for high-rate

applications.

The seal is typically a plastic material, such as nylon or polypropylene. It is combined with sev-

eral metal parts that include the brass collector and cover to form the collector assembly. It seals off

the open end of the cylindrical can. After it is crimped in place, it prevents leakage of the electrolyte

from the cell and provides electrical insulation between the can (positive electrode) and the anode

(negative electrode).

The remaining components of the alkaline cell include the label and metal disks at either end of

the cell to provide the negative and positive electrode contacts. The label on most current alkaline

cell designs is a plastic label that is heat-shrunk onto the can. This has been another recent design

feature that allows the can to be larger in diameter, which results in a greater input capacity.

Miniature Cell. The components that make up the miniature cell are essentially the same as those

of the cylindrical cell, but scaled down. The can that contains the molded cathode pellet is typically

made of mild steel plated on both sides with nickel. Some can designs are even made of a triclad

metal material. The seal is a thin plastic gasket, and the separator is the typical nonwoven material.

The anode cup, which contains the anode gel, is then pressed into the seal to complete the cell. The

outside of the cell contains the manufacturer’s logo and cell-size identification.

11.4 CONSTRUCTION

11.4.1 Cylindrical Design

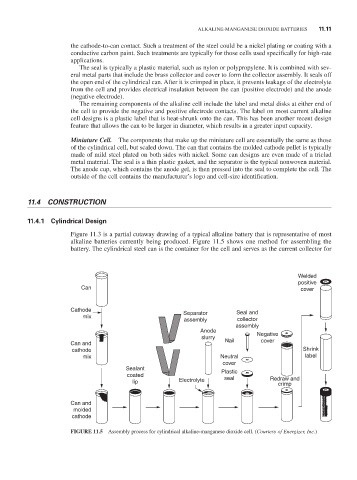

Figure 11.3 is a partial cutaway drawing of a typical alkaline battery that is representative of most

alkaline batteries currently being produced. Figure 11.5 shows one method for assembling the

battery. The cylindrical steel can is the container for the cell and serves as the current collector for

Welded

positive

Can cover

Cathode Separator Seal and

mix

assembly collector

assembly

Anode Negative

slurry

Can and Nail cover

cathode Shrink

mix Neutral label

cover

Sealant Plastic

coated seal Redraw and

lip Electrolyte crimp

Can and

molded

cathode

FiguRE 11.5 Assembly process for cylindrical alkaline-manganese dioxide cell. (Courtesy of Energizer, Inc.)