Page 269 - Lindens Handbook of Batteries

P. 269

ALKALINE-MANGANESE DIOXIDE BATTERIES 11.7

While the hydrogen evolution rate of pure zinc is low, the inevitable presence of impurities, i.e.,

traces of ppm levels, promotes the rate of gassing by acting as cathodic sites on the zinc. This gas-

sing can be reduced or minimized in several of the following ways: (1) alloying the zinc with known

gassing inhibiting elements, (2) reducing the impurity levels of the cell components, (3) adding ZnO

to the anode, and (4) adding inorganic or organic gassing inhibitors (e.g., pEG, polyethylene glycol)

to the anode. Mercury is the best and most efficient inhibitor, but due to its toxic nature and the

international drive for green chemistry, has been banned for use in alkaline cells worldwide.

Alloying elements are incorporated into the zinc to both inhibit gassing and improve perfor-

mance. The main group of such elements includes lead, bismuth, thallium, and indium. The levels of

these elements have been empirically determined based on the performance required by the battery

manufacturer.

As already mentioned, the impurity levels in the zinc should be as low as possible, with most of

them coming from the natural ore or during processing. Their levels are typically determined by the

efficiency of the zinc powder process.

Another important aspect of the zinc reaction in alkaline solution is its equilibrium with its ion in

solution. The zinc metal anode is in equilibrium with the zinc ions in the KOH solution. Therefore,

on stand, the zinc electrode reaction is continually dissolving and redepositing in the anode com-

partment of the cell. It has been shown by detailed SEM studies that both type I and type II zinc

oxides are present in the discharged zinc particles in the porous anode. The morphology of these

two different zinc types appears to depend on the drain rate, i.e., the current density, of the zinc dur-

ing discharge in a cell and is produced by a solution-precipitation reaction. While most of the zinc

particles are discharged, the core of undischarged zinc is covered with these two oxides. At low drain

rates, the distribution of ZnO is uniformly distributed within the anode, while at high drain rates, the

ZnO mainly forms near the separator. 5,6

11.3 CELL COmPONENTS AND mATERIALS

11.3.1 Cathode Components

The typical composition of an alkaline cathode and its functions are listed in Table 11.4. The cath-

ode is basically a mixture of manganese dioxide and carbon (typically graphite), binder (typically

portland cement or polymers), along with cell electrolyte. However, other materials may be also

present, such as binders, additional water, and/or more electrolyte solution.

Manganese Dioxide. The manganese dioxide is the positive electrode of the cell or the oxidizing

component. It must be highly active and very pure as it basically determines the battery’s OCV and

shape of the discharge curve during use.

The production of high-quality EMD basically involves multiple steps over a period of time.

The natural manganese dioxide dug out of the ground is first calcined to form MnO. The MnO is

then dissolved in sulfuric acid to produce a manganese sulfate solution. This solution then goes

through an electrolyte purification step to remove most of the deleterious heavy metal impurities,

e.g., Fe, Cu, Co, Ni, Mo, Cr. This purified solution is then placed in an electrolysis cell and heated

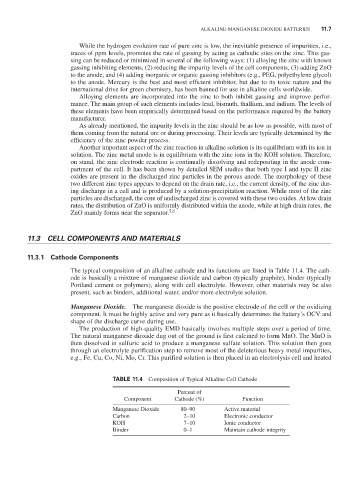

TABLE 11.4 Composition of Typical Alkaline Cell Cathode

percent of

Component Cathode (%) Function

Manganese Dioxide 80–90 Active material

Carbon 2–10 Electronic conductor

KOH 7–10 Ionic conductor

Binder 0–1 Maintain cathode integrity