Page 40 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 40

28 Low-Temperature Energy Systems with Applications of Renewable Energy

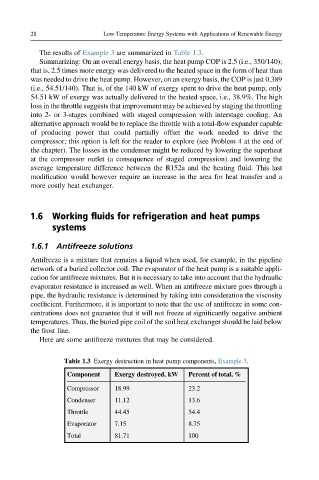

The results of Example 3 are summarized in Table 1.3.

Summarizing: On an overall energy basis, the heat pump COP is 2.5 (i.e., 350/140);

that is, 2.5 times more energy was delivered to the heated space in the form of heat than

was needed to drive the heat pump. However, on an exergy basis, the COP is just 0.389

(i.e., 54.51/140). That is, of the 140 kW of exergy spent to drive the heat pump, only

54.51 kW of exergy was actually delivered to the heated space, i.e., 38.9%. The high

loss in the throttle suggests that improvement may be achieved by staging the throttling

into 2- or 3-stages combined with staged compression with interstage cooling. An

alternative approach would be to replace the throttle with a total-flow expander capable

of producing power that could partially offset the work needed to drive the

compressor; this option is left for the reader to explore (see Problem 4 at the end of

the chapter). The losses in the condenser might be reduced by lowering the superheat

at the compressor outlet (a consequence of staged compression) and lowering the

average temperature difference between the R152a and the heating fluid. This last

modification would however require an increase in the area for heat transfer and a

more costly heat exchanger.

1.6 Working fluids for refrigeration and heat pumps

systems

1.6.1 Antifreeze solutions

Antifreeze is a mixture that remains a liquid when used, for example, in the pipeline

network of a buried collector coil. The evaporator of the heat pump is a suitable appli-

cation for antifreeze mixtures. But it is necessary to take into account that the hydraulic

evaporator resistance is increased as well. When an antifreeze mixture goes through a

pipe, the hydraulic resistance is determined by taking into consideration the viscosity

coefficient. Furthermore, it is important to note that the use of antifreeze in some con-

centrations does not guarantee that it will not freeze at significantly negative ambient

temperatures. Thus, the buried pipe coil of the soil heat exchanger should be laid below

the frost line.

Here are some antifreeze mixtures that may be considered.

Table 1.3 Exergy destruction in heat pump components, Example 3.

Component Exergy destroyed, kW Percent of total, %

Compressor 18.99 23.2

Condenser 11.12 13.6

Throttle 44.45 54.4

Evaporator 7.15 8.75

Total 81.71 100