Page 119 - MEMS Mechanical Sensors

P. 119

108 Mechanical Transduction Techniques

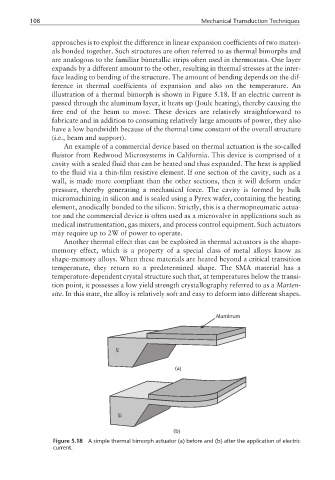

approaches is to exploit the difference in linear expansion coefficients of two materi-

als bonded together. Such structures are often referred to as thermal bimorphs and

are analogous to the familiar bimetallic strips often used in thermostats. One layer

expands by a different amount to the other, resulting in thermal stresses at the inter-

face leading to bending of the structure. The amount of bending depends on the dif-

ference in thermal coefficients of expansion and also on the temperature. An

illustration of a thermal bimorph is shown in Figure 5.18. If an electric current is

passed through the aluminum layer, it heats up (Joule heating), thereby causing the

free end of the beam to move. These devices are relatively straightforward to

fabricate and in addition to consuming relatively large amounts of power, they also

have a low bandwidth because of the thermal time constant of the overall structure

(i.e., beam and support).

An example of a commercial device based on thermal actuation is the so-called

fluistor from Redwood Microsystems in California. This device is comprised of a

cavity with a sealed fluid that can be heated and thus expanded. The heat is applied

to the fluid via a thin-film resistive element. If one section of the cavity, such as a

wall, is made more compliant than the other sections, then it will deform under

pressure, thereby generating a mechanical force. The cavity is formed by bulk

micromachining in silicon and is sealed using a Pyrex wafer, containing the heating

element, anodically bonded to the silicon. Strictly, this is a thermopneumatic actua-

tor and the commercial device is often used as a microvalve in applications such as

medical instrumentation, gas mixers, and process control equipment. Such actuators

may require up to 2W of power to operate.

Another thermal effect that can be exploited in thermal actuators is the shape-

memory effect, which is a property of a special class of metal alloys know as

shape-memory alloys. When these materials are heated beyond a critical transition

temperature, they return to a predetermined shape. The SMA material has a

temperature-dependent crystal structure such that, at temperatures below the transi-

tion point, it possesses a low yield strength crystallography referred to as a Marten-

site. In this state, the alloy is relatively soft and easy to deform into different shapes.

Aluminum

Si

(a)

Si

(b)

Figure 5.18 A simple thermal bimorph actuator (a) before and (b) after the application of electric

current.