Page 63 - MEMS Mechanical Sensors

P. 63

52 MEMS Simulation and Design Tools

Preprocessor Solution Postprocessor

Element type Analysis type Read results

Material properties Define loads by set

Define geometry Load set options by load step

Mesh attributes Solve by time/frequency

Model checking View element/nodal results

Save results (prestress and

fatigue analysis)

Figure 3.10 Typical ANSYS routine.

1

1 1 1 1 ANSYS

1 1 1

1 1

1 1

1 1 1 1

1 1 1 1 1 1

1 1 1 1

1 1 1 1

1 1 1

1

1 1 1 2 1 1 1 1 1 1

2 2 2 1 1 1

2 2 1 1

2 2 1

2 2 1

2

1 2 2

1 2

2

2 2 2 1

1 2 1 1

1 2 1

1 1 1 1 1

1 1 1 1

1 1

1 1 1 1 1

1 1

1 1 1 1

1 1 1 1

1 1 1

1

1

1 1 1 1

1 1 1 1 1

1

1

1 1 1 1 1 1

1 1

1

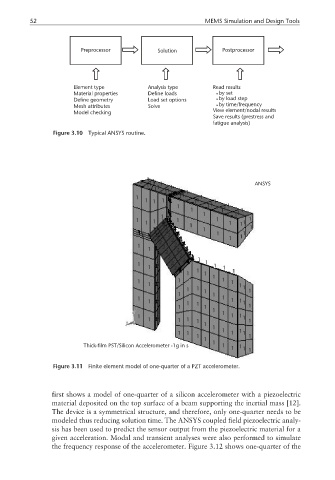

Thick-film PST/Silicon Accelerometer -1g in s 1 1 1 1 1 1

Figure 3.11 Finite element model of one-quarter of a PZT accelerometer.

first shows a model of one-quarter of a silicon accelerometer with a piezoelectric

material deposited on the top surface of a beam supporting the inertial mass [12].

The device is a symmetrical structure, and therefore, only one-quarter needs to be

modeled thus reducing solution time. The ANSYS coupled field piezoelectric analy-

sis has been used to predict the sensor output from the piezoelectric material for a

given acceleration. Modal and transient analyses were also performed to simulate

the frequency response of the accelerometer. Figure 3.12 shows one-quarter of the