Page 205 - MEMS and Microstructures in Aerospace Applications

P. 205

Osiander / MEMS and microstructures in Aerospace applications DK3181_c009 Final Proof page 196 1.9.2005 12:07pm

196 MEMS and Microstructures in Aerospace Applications

Polymer

Radiator

Supports Substrate Gold Sputtered Nitride

(SU8) Membrane (Electrically Insulating)

FIGURE 9.5 A schematic of SU8 fabricated device.

electrostatically attracted to the radiator and makes thermal contact, connecting the

radiator to the high emissivity surface. The disadvantage of this design is the high

switching voltage, typically greater than 400 V.

A similar design has been developed and fabricated in a MEMS platform by the

United States Naval Academy (USNA) and JHU/APL, to be flown on the USNA

Midstar satellite. For this design, the radiator consists of an array of membranes,

about 400 to 500 mm wide and long, suspended a couple of microns above the

surface on frames or posts at the corner. Figure 9.5 shows a schematic of the device,

which is fabricated using SU8, a photosensitive epoxy with a very low thermal

conductivity in the cured state, and a gold membrane. An example of a frame-

supported device is shown in Figure 9.6. The devices have switching voltages

between 20 and 40 V, very well within spacecraft standard voltages. While the

MEMS design performs well, the thermal design needs to be improved. The thermal

conductance in the off state, given by the conductivity in the support posts, is very

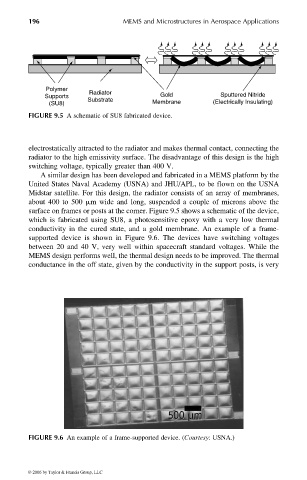

FIGURE 9.6 An example of a frame-supported device. (Courtesy: USNA.)

© 2006 by Taylor & Francis Group, LLC