Page 262 - MEMS and Microstructures in Aerospace Applications

P. 262

Osiander / MEMS and microstructures in Aerospace applications DK3181_c011 Final Proof page 253 1.9.2005 12:31pm

Micropropulsion Technologies 253

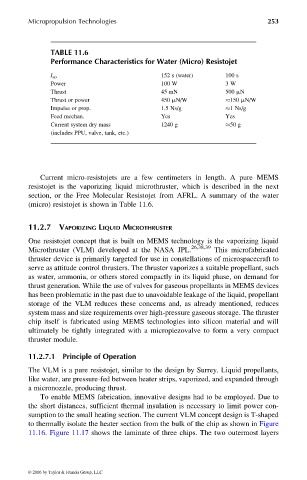

TABLE 11.6

Performance Characteristics for Water (Micro) Resistojet

I sp 152 s (water) 100 s

Power 100 W 3 W

Thrust 45 mN 500 mN

Thrust or power 450 mN/W 150 mN/W

Impulse or prop. 1.5 Ns/g 1 Ns/g

Feed mechan. Yes Yes

Current system dry mass 1240 g 50 g

(includes PPU, valve, tank, etc.)

Current micro-resistojets are a few centimeters in length. A pure MEMS

resistojet is the vaporizing liquid microthruster, which is described in the next

section, or the Free Molecular Resistojet from AFRL. A summary of the water

(micro) resistojet is shown in Table 11.6.

11.2.7 VAPORIZING LIQUID MICROTHRUSTER

One resistojet concept that is built on MEMS technology is the vaporizing liquid

26,38,39

Microthruster (VLM) developed at the NASA JPL. This microfabricated

thruster device is primarily targeted for use in constellations of microspacecraft to

serve as attitude control thrusters. The thruster vaporizes a suitable propellant, such

as water, ammonia, or others stored compactly in its liquid phase, on demand for

thrust generation. While the use of valves for gaseous propellants in MEMS devices

has been problematic in the past due to unavoidable leakage of the liquid, propellant

storage of the VLM reduces these concerns and, as already mentioned, reduces

system mass and size requirements over high-pressure gaseous storage. The thruster

chip itself is fabricated using MEMS technologies into silicon material and will

ultimately be tightly integrated with a micropiezovalve to form a very compact

thruster module.

11.2.7.1 Principle of Operation

The VLM is a pure resistojet, similar to the design by Surrey. Liquid propellants,

like water, are pressure-fed between heater strips, vaporized, and expanded through

a micronozzle, producing thrust.

To enable MEMS fabrication, innovative designs had to be employed. Due to

the short distances, sufficient thermal insulation is necessary to limit power con-

sumption to the small heating section. The current VLM concept design is T-shaped

to thermally isolate the heater section from the bulk of the chip as shown in Figure

11.16. Figure 11.17 shows the laminate of three chips. The two outermost layers

© 2006 by Taylor & Francis Group, LLC