Page 270 - MEMS and Microstructures in Aerospace Applications

P. 270

Osiander / MEMS and microstructures in Aerospace applications DK3181_c011 Final Proof page 261 1.9.2005 12:31pm

Micropropulsion Technologies 261

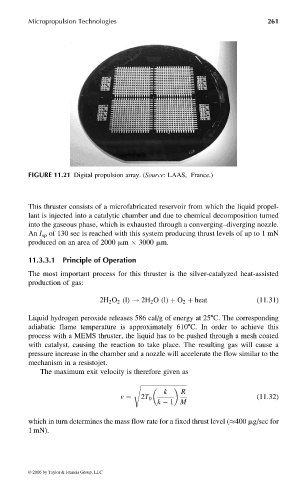

FIGURE 11.21 Digital propulsion array. (Source: LAAS, France.)

This thruster consists of a microfabricated reservoir from which the liquid propel-

lant is injected into a catalytic chamber and due to chemical decomposition turned

into the gaseous phase, which is exhausted through a converging–diverging nozzle.

An I sp of 130 sec is reached with this system producing thrust levels of up to 1 mN

produced on an area of 2000 mm 3000 mm.

11.3.3.1 Principle of Operation

The most important process for this thruster is the silver-catalyzed heat-assisted

production of gas:

2H 2 O 2 (l) ! 2H 2 O (l) þ O 2 þ heat (11:31)

Liquid hydrogen peroxide releases 586 cal/g of energy at 258C. The corresponding

adiabatic flame temperature is approximately 6108C. In order to achieve this

process with a MEMS thruster, the liquid has to be pushed through a mesh coated

with catalyst, causing the reaction to take place. The resulting gas will cause a

pressure increase in the chamber and a nozzle will accelerate the flow similar to the

mechanism in a resistojet.

The maximum exit velocity is therefore given as

s ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

k R

v ¼ 2T 0 (11:32)

k 1 M

which in turn determines the mass flow rate for a fixed thrust level ( 400 mg/sec for

1 mN).

© 2006 by Taylor & Francis Group, LLC