Page 320 - MEMS and Microstructures in Aerospace Applications

P. 320

Osiander / MEMS and microstructures in Aerospace applications DK3181_c014 Final Proof page 314 1.9.2005 12:47pm

314 MEMS and Microstructures in Aerospace Applications

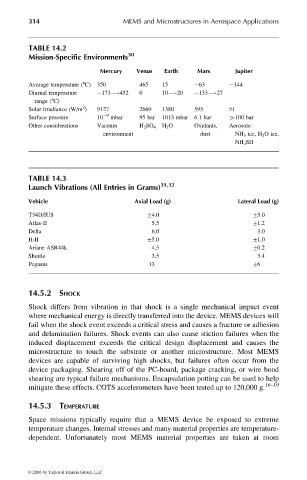

TABLE 14.2

Mission-Specific Environments 30

Mercury Venus Earth Mars Jupiter

Average temperature (8C) 350 465 15 63 144

Diurnal temperature 173 !452 0 10 !20 133 !27

range (8C)

2

Solar irradiance (W/m ) 9127 2660 1380 595 51

Surface pressure 10 9 mbar 95 bar 1013 mbar 6.1 bar 100 bar

Other considerations Vacuum H 2 SO 4 H 2 O Oxidants, Aerosols:

environment dust NH 3 ice, H 2 O ice,

NH 4 SH

TABLE 14.3

Launch Vibrations (All Entries in Grams) 31,32

Vehicle Axial Load (g) Lateral Load (g)

T34D/IUS +4.0 +5.0

Atlas-II 5.5 +1.2

Delta 6.0 3.0

H-II +5.0 +1.0

Ariane ASR44L 4.5 +0.2

Shuttle 3.5 3.4

Pegasus 13 +6

14.5.2 SHOCK

Shock differs from vibration in that shock is a single mechanical impact event

where mechanical energy is directly transferred into the device. MEMS devices will

fail when the shock event exceeds a critical stress and causes a fracture or adhesion

and delamination failures. Shock events can also cause stiction failures when the

induced displacement exceeds the critical design displacement and causes the

microstructure to touch the substrate or another microstructure. Most MEMS

devices are capable of surviving high shocks, but failures often occur from the

device packaging. Shearing off of the PC-board, package cracking, or wire bond

shearing are typical failure mechanisms. Encapsulation potting can be used to help

mitigate these effects. COTS accelerometers have been tested up to 120,000 g. 16–19

14.5.3 TEMPERATURE

Space missions typically require that a MEMS device be exposed to extreme

temperature changes. Internal stresses and many material properties are temperature-

dependent. Unfortunately most MEMS material properties are taken at room

© 2006 by Taylor & Francis Group, LLC