Page 351 -

P. 351

X-Ray–Based Fabrication 5-13

TABLE 5.4 Properties of PMMA (nom. at 20°C)

E – bulk modulus 3.0 GPa

G – shear modulus 1.7 GPa

ν – Poisson’s ratio 0.40

–5

α – linear thermal coefficient of expansion 7(10) /°C

Water absorption (by wt. %)

(during immersion)

– 24 hrs. 0.2%

– 7 days 0.5%

– 21 days 0.8%

– 48 days 1.1%

Glass transition temperature 105°C

σ – tensile strength 70 Mpa

Y

δ – density 1.19g/cc

κ – thermal conductivity 0.193 W/m

K

Heat capacity 1.42 J/g

K

n – refractive index at 365 nm, 1014nm 1.514, 1.483

Abbe number 58.0

ε – dielectric constant

r

– 60 Hz 3.5

– 1kHz 3.0

– 1MHz 2.6

– 30GHz 2.57

4 8 12 16 20

0.5 Plate

thickness (µm)

0.4

Plate buckling strain (%) 0.3

0.2

0.1

0

0 100 200 300 400 500

PMMA plate height (µm)

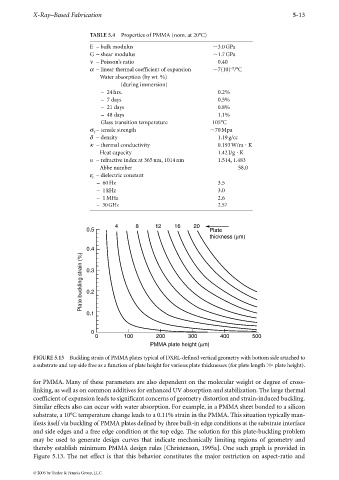

FIGURE 5.13 Buckling strain of PMMA plates typical of DXRL-defined vertical geometry with bottom side attached to

a substrate and top side free as a function of plate height for various plate thicknesses (for plate length plate height).

for PMMA. Many of these parameters are also dependent on the molecular weight or degree of cross-

linking, as well as on common additives for enhanced UV absorption and stabilization. The large thermal

coefficient of expansion leads to significant concerns of geometry distortion and strain-induced buckling.

Similar effects also can occur with water absorption. For example, in a PMMA sheet bonded to a silicon

substrate, a 10°C temperature change leads to a 0.11% strain in the PMMA. This situation typically man-

ifests itself via buckling of PMMA plates defined by three built-in edge conditions at the substrate interface

and side edges and a free edge condition at the top edge. The solution for this plate-buckling problem

may be used to generate design curves that indicate mechanically limiting regions of geometry and

thereby establish minimum PMMA design rules [Christenson, 1995a]. One such graph is provided in

Figure 5.13. The net effect is that this behavior constitutes the major restriction on aspect-ratio and

© 2006 by Taylor & Francis Group, LLC