Page 323 - Machinery Component Maintenance

P. 323

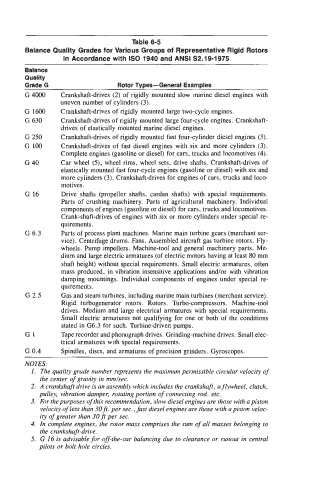

Table 6-5

Balance Quality Grades for Various Groups of Representative Rigid Rotors

in Accordance with IS0 1940 and ANSI S2.19-1975

Balance

Quality

Grade G Rotor Types-General Examples

G 4000 Crankshaft-drives (2) of rigidly mounted slow marine diesel engines with

uneven number of cylinders (3).

G 1600 Crankshaft-drives of rigidly mounted large two-cycle engines.

G 630 Crankshaft-drives of rigidly mounted large four-cycle engines. Crankshaft-

drives of elastically mounted marine diesel engines.

G 250 Crankshaft-drives of rigidly mounted fast four-cylinder diesel engines (3).

G 100 Crankshaft-drives of fast diesel engines with six and more cylinders (3).

Complete engines (gasoline or diesel) for cars, trucks and locomotives (4).

G 40 Car wheel (5), wheel rims, wheel sets, drive shafts. Crankshaft-drives of

elastically mounted fast four-cycle engines (gasoline or diesel) with six and

more cylinders (3). Crankshaft-drives for engines of cars, trucks and loco-

motives.

G 16 Drive shafts (propeller shafts, cardan shafts) with special requirements.

Parts of crushing machinery. Parts of agricultural machinery. Individual

components of engines (gasoline or diesel) for cars, trucks and locomotives.

Crank-shaft-drives of engines with six or more cylinders under special re-

quirements.

G 6.3 Parts of process plant machines. Marine main turbine gears (merchant ser-

vice). Centrifuge drums. Fans. Assembled aircraft gas turbine rotors. Fly-

wheels. Pump impellers. Machine-tool and general machinery parts. Me-

dium and large electric armatures (of electric motors having at least 80 mm

shaft height) without special requirements. Small electric armatures, often

mass produced, in vibration insensitive applications and/or with vibration

damping mountings. Individual components of engines under special re-

quirements.

G 2.5 Gas and steam turbines, including marine main turbines (merchant service).

Rigid turbogenerator rotors. Rotors. Turbo-compressors. Machine-tool

drives. Medium and large electrical armatures with special requirements.

Small electric armatures not qualifying for one or both of the conditions

stated in G6.3 for such. 'hrbine-driven pumps.

GI Tape recorder and phonograph drives. Grinding-machine drives. Small elec-

trical armatures with special requirements.

G 0.4 Spindles, discs, and armatures of precision grinders. Gyroscopes.

NOTES:

1. The quality grade number represents the maximum permissible circular velocity of

the center of gravity in mm/sec.

2: A crankshaft drive is an assembly which includes the crankshaft, a flywheel, clutch,

pulley, vibration damper, rotating portion of connecting rod, etc.

3. For the purposes of this recommendation, slow diesel engines are those with a piston

velocity of less than 30 ft. per sec., fast diesel engines are those with a piston veloc-

ity of greater than 30 ft per sec.

4. In complete engines, the rotor mass comprises the sum of all masses belonging to

the crankshaft-drive.

5. G 16 is advisable for off-the-car balancing due to clearance or runout in central

pilots or bolt hole circles.