Page 345 - Machinery Component Maintenance

P. 345

Balancing of Machinery Components 327

Solution: Field Balancing in Several Planes

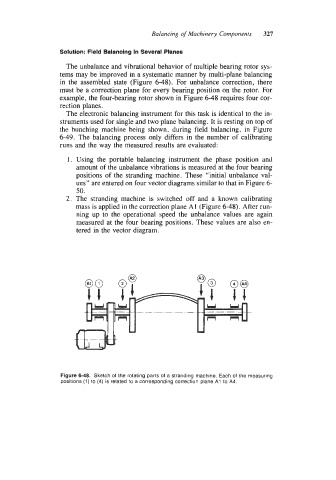

The unbalance and vibrational behavior of multiple bearing rotor sys-

tems may be improved in a systematic manner by multi-plane balancing

in the assembled state (Figure 648). For unbalance correction, there

must be a correction plane for every bearing position on the rotor. For

example, the four-bearing rotor shown in Figure 648 requires four cor-

rection planes.

The electronic balancing instrument for this task is identical to the in-

struments used for single and two plane balancing. It is resting on top of

the bunching machine being shown, during field balancing, in Figure

6-49. The balancing process only differs in the number of calibrating

runs and the way the measured results are evaluated:

1. Using the portable balancing instrument the phase position and

amount of the unbalance vibrations is measured at the four bearing

positions of the stranding machine. These “initial unbalance val-

ues” are entered on four vector diagrams similar to that in Figure 6-

50.

2. The stranding machine is switched off and a known calibrating

mass is applied in the correction plane A1 (Figure 6-48). After run-

ning up to the operational speed the unbalance values are again

measured at the four bearing positions. These values are also en-

tered in the vector diagram.

Figure 6-48. Sketch of the rotating parts of a stranding machine. Each of the measuring

positions (1) to (4) is related to a corresponding correction plane AI to A4.