Page 42 - Machinery Component Maintenance

P. 42

Maintenance Organization ana' Control for Multi-Plant Corporations 27

r I - 4

WANE SECTION 1 1

FREOUENCV

EOUI?NENl

MZi

I SUBSECTION I 1 Zpg NAN

HRS

NUYttR- , NAlNlrwrlCE 21,s s, AS lNOlCATE0 REO

Ol.lG.31 K)l Check for unusua. nolse or vlbratlon at motor. IX I 1

Main Air I speea increaser, compressor and main oil pump.

Lorpressor

(Uechanical) '

IO2 ' ChecL pressure drop across oil filter IX ' I

(Items 140) Vent spue filter and mvitcn filters lf DP I

Iexceeds 35 lbs. Clean ann vent dirty filter.

I

I I

p3 i Check level in oil reservoir ana ado oil to ' I ~

1 I Record mmounr 8ddcn. I

brinR to the Wl - hegal Oil A (HLO).

MIA

I

operation

08 1 Check lube oil system for leaks Md repalr dl X

possible

I

09 1 Inspect air 1erk.g~ at caslng ana labyrinth

i sedr for ch-e in 1eAa.s.e

' I surge valve.Md discharge check valve for

10 i Check linkwe on inlet butterfly valve

proper lubrication ana evidence of corrosion

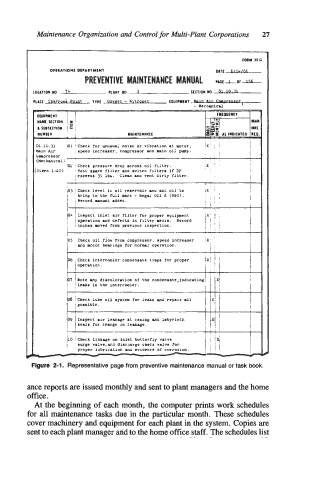

Figure 2-1. Representative page from preventive maintenance manual or task book.

ance reports are issued monthly and sent to plant managers and the home

office.

At the beginning of each month, the computer prints work schedules

for all maintenance tasks due in the particular month. These schedules

cover machinery and equipment for each plant in the system. Copies are

sent to each plant manager and to the home office staff. The schedules list