Page 194 - Make Your Own PCBs with EAGLE from Schematic Designs to Finished Boards

P. 194

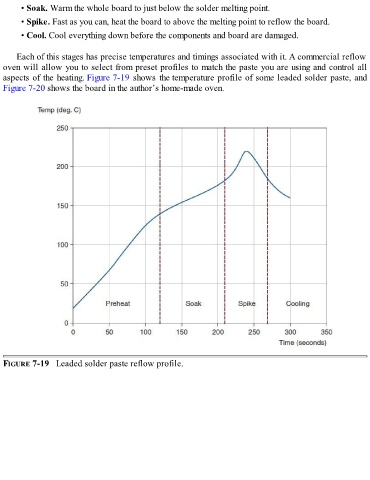

• Soak. Warm the whole board to just below the solder melting point.

• Spike. Fast as you can, heat the board to above the melting point to reflow the board.

• Cool. Cool everything down before the components and board are damaged.

Each of this stages has precise temperatures and timings associated with it. A commercial reflow

oven will allow you to select from preset profiles to match the paste you are using and control all

aspects of the heating. Figure 7-19 shows the temperature profile of some leaded solder paste, and

Figure 7-20 shows the board in the author’s home-made oven.

FIGURE 7-19 Leaded solder paste reflow profile.