Page 227 - Making things move_ DIY mechanisms for inventors, hobbyists, and artists

P. 227

Chapter 7 Bearings, Couplers, Gears, Screws, and Springs 205

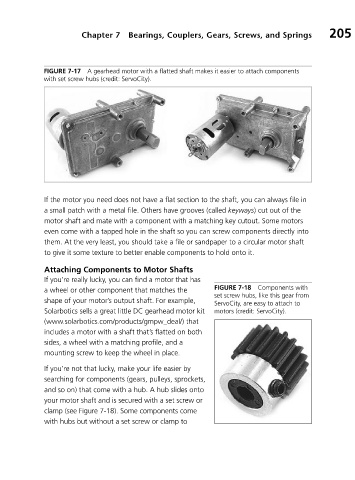

FIGURE 7-17 A gearhead motor with a flatted shaft makes it easier to attach components

with set screw hubs (credit: ServoCity).

If the motor you need does not have a flat section to the shaft, you can always file in

a small patch with a metal file. Others have grooves (called keyways) cut out of the

motor shaft and mate with a component with a matching key cutout. Some motors

even come with a tapped hole in the shaft so you can screw components directly into

them. At the very least, you should take a file or sandpaper to a circular motor shaft

to give it some texture to better enable components to hold onto it.

Attaching Components to Motor Shafts

If you’re really lucky, you can find a motor that has

a wheel or other component that matches the FIGURE 7-18 Components with

set screw hubs, like this gear from

shape of your motor’s output shaft. For example,

ServoCity, are easy to attach to

Solarbotics sells a great little DC gearhead motor kit motors (credit: ServoCity).

(www.solarbotics.com/products/gmpw_deal/) that

includes a motor with a shaft that’s flatted on both

sides, a wheel with a matching profile, and a

mounting screw to keep the wheel in place.

If you’re not that lucky, make your life easier by

searching for components (gears, pulleys, sprockets,

and so on) that come with a hub. A hub slides onto

your motor shaft and is secured with a set screw or

clamp (see Figure 7-18). Some components come

with hubs but without a set screw or clamp to