Page 228 - Making things move_ DIY mechanisms for inventors, hobbyists, and artists

P. 228

206 Making Things Move

secure them. The term for this is plain bore. If the fit is too loose, you can always drill

and tap your own hole for a set screw. (See Chapter 3 for details on how to drill and

tap holes.)

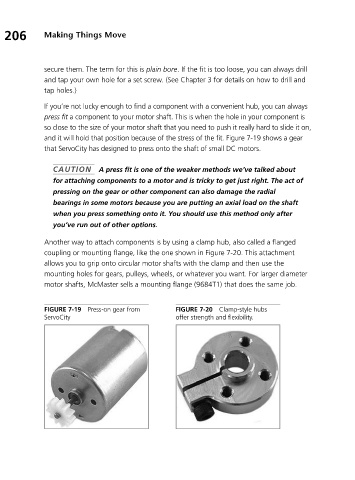

If you’re not lucky enough to find a component with a convenient hub, you can always

press fit a component to your motor shaft. This is when the hole in your component is

so close to the size of your motor shaft that you need to push it really hard to slide it on,

and it will hold that position because of the stress of the fit. Figure 7-19 shows a gear

that ServoCity has designed to press onto the shaft of small DC motors.

CAUTION A press fit is one of the weaker methods we’ve talked about

for attaching components to a motor and is tricky to get just right. The act of

pressing on the gear or other component can also damage the radial

bearings in some motors because you are putting an axial load on the shaft

when you press something onto it. You should use this method only after

you’ve run out of other options.

Another way to attach components is by using a clamp hub, also called a flanged

coupling or mounting flange, like the one shown in Figure 7-20. This attachment

allows you to grip onto circular motor shafts with the clamp and then use the

mounting holes for gears, pulleys, wheels, or whatever you want. For larger diameter

motor shafts, McMaster sells a mounting flange (9684T1) that does the same job.

FIGURE 7-19 Press-on gear from FIGURE 7-20 Clamp-style hubs

ServoCity offer strength and flexibility.