Page 230 - Making things move_ DIY mechanisms for inventors, hobbyists, and artists

P. 230

208 Making Things Move

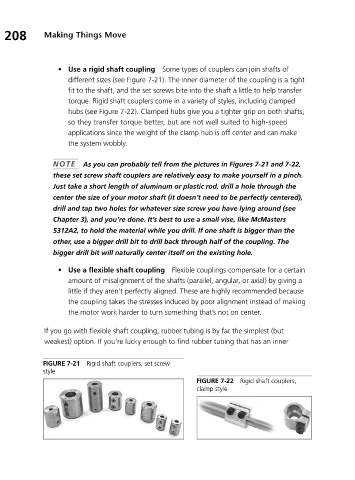

• Use a rigid shaft coupling Some types of couplers can join shafts of

different sizes (see Figure 7-21). The inner diameter of the coupling is a tight

fit to the shaft, and the set screws bite into the shaft a little to help transfer

torque. Rigid shaft couplers come in a variety of styles, including clamped

hubs (see Figure 7-22). Clamped hubs give you a tighter grip on both shafts,

so they transfer torque better, but are not well suited to high-speed

applications since the weight of the clamp hub is off center and can make

the system wobbly.

NOTE As you can probably tell from the pictures in Figures 7-21 and 7-22,

these set screw shaft couplers are relatively easy to make yourself in a pinch.

Just take a short length of aluminum or plastic rod, drill a hole through the

center the size of your motor shaft (it doesn’t need to be perfectly centered),

drill and tap two holes for whatever size screw you have lying around (see

Chapter 3), and you’re done. It’s best to use a small vise, like McMasters

5312A2, to hold the material while you drill. If one shaft is bigger than the

other, use a bigger drill bit to drill back through half of the coupling. The

bigger drill bit will naturally center itself on the existing hole.

• Use a flexible shaft coupling Flexible couplings compensate for a certain

amount of misalignment of the shafts (parallel, angular, or axial) by giving a

little if they aren’t perfectly aligned. These are highly recommended because

the coupling takes the stresses induced by poor alignment instead of making

the motor work harder to turn something that’s not on center.

If you go with flexible shaft coupling, rubber tubing is by far the simplest (but

weakest) option. If you’re lucky enough to find rubber tubing that has an inner

FIGURE 7-21 Rigid shaft couplers, set screw

style

FIGURE 7-22 Rigid shaft couplers,

clamp style